Restoring outdated bikes is greater than only a passion as a Cafe Racer. For a lot of, it’s a solution to be taught new expertise, tackle inventive challenges, and construct one thing really distinctive. Every mission provides an opportunity to strive completely different strategies and convey new life to forgotten machines.

This text follows one particular person’s journey as they carry a rusty 1981 Yamaha XJ650 again to life. The method contains fixing mechanical points, including customized elements, and making daring design decisions. By means of arduous work, endurance, and assist from others, this construct exhibits how rewarding it may be to see an concept flip into actuality.

Key Takeaways

- Restoring outdated bikes is an opportunity to construct expertise and take a look at new concepts.

- Customized work and a spotlight to element make every mission particular.

- Ending a motorbike takes endurance, teamwork, and dedication.

Why Restoring Previous Bikes Feels Rewarding

Selecting Up Helpful Talents

Restoring outdated bikes provides folks the possibility to be taught by doing. Every step, like taking aside the engine or fixing the body, teaches one thing new. They could strive issues they by no means thought they might do, resembling utilizing 3D printing or welding new items onto the bike. Errors do occur, however attempting once more helps them get higher over time.

Right here’s a brief checklist of what they could be taught:

- Utilizing new instruments like CNC machines

- Studying about 3D modeling and printing

- Understanding easy methods to set up and wire electrical elements

Professional Tip: Even when one thing appears arduous at first, observe makes it simpler.

Letting Creativeness Lead the Approach

Restoring isn’t just about repairs; it’s about creating one thing particular. Builders typically check out daring concepts, like becoming a thick rear wheel or including a singular twin headlight. There is no such thing as a single “proper” method — each mission will be completely different.

| Artistic Decisions | Instance |

|---|---|

| Customized Paint | Mixing new colours for the physique |

| Distinctive Components | 3D printed exhaust ideas |

| Customized Design | Handmade seat or tailights |

Builders take pleasure in watching their concepts grow to be actual. Each small element, like new nuts or a clear body, provides up and makes the bike really their very own.

Mission Overview: 1981 Yamaha XJ650

Major Targets for the Yamaha Construct

The plan for this bike is to create a contemporary basic. The proprietor needs it to maintain its old-school fashion however use new constructing strategies. This contains making customized elements, like CNC bump stops and 3D printed metallic ideas, to provide the bike a contemporary look.

There’s a robust concentrate on studying new expertise throughout the course of. Constructing this bike means attempting issues which have by no means been finished earlier than by the builder. The mission is about having fun with the journey, choosing up new data, and constructing one thing distinctive with private touches.

Key Construct Targets:

- Preserve the retro look

- Use new strategies and instruments

- Make customized items for various elements

- Add particular touches, like a chunky rear wheel and distinctive headlights

Going through Rust and Onerous Work from the Begin

This 1981 Yamaha XJ650 began out in tough form, with plenty of rust. Getting the bike working was the primary powerful step. The work included including new filters and fluids to verify the engine may run easily.

A lot of the duties, like chopping the rear finish and welding on new elements, had been new to the proprietor. There was plenty of trial and error. Fixing the bike took over two and a half years, and each stage—cleansing the engine, sorting the powder coating, doing the wiring—had its personal issues.

Duties That Wanted Additional Effort:

| Step | Problem |

|---|---|

| Restoring the body | Heavy rust |

| Customized elements fabrication | Studying new strategies |

| Wiring the electrics | Inexperience |

| Lengthy construct time | Over 2.5 years |

Even with all the difficulty, each small win and accomplished job made the trouble value it. The method was gradual and wanted plenty of endurance, however seeing the outdated bike come collectively was very rewarding.

Getting the Bike Able to Begin

Swapping Filters and Fluids

Step one was to vary out all of the outdated filters and fluids. They put in a contemporary oil filter and new oil. The air filter was soiled, so it acquired changed too. Coolant and brake fluid had been each swapped with clear, new fluids. This helps the engine and different elements work higher and last more.

A fast guidelines for these steps:

- Change oil and oil filter

- Exchange air filter

- Fill with contemporary coolant

- Add contemporary brake fluid

These small steps made an enormous distinction for getting the bike able to run.

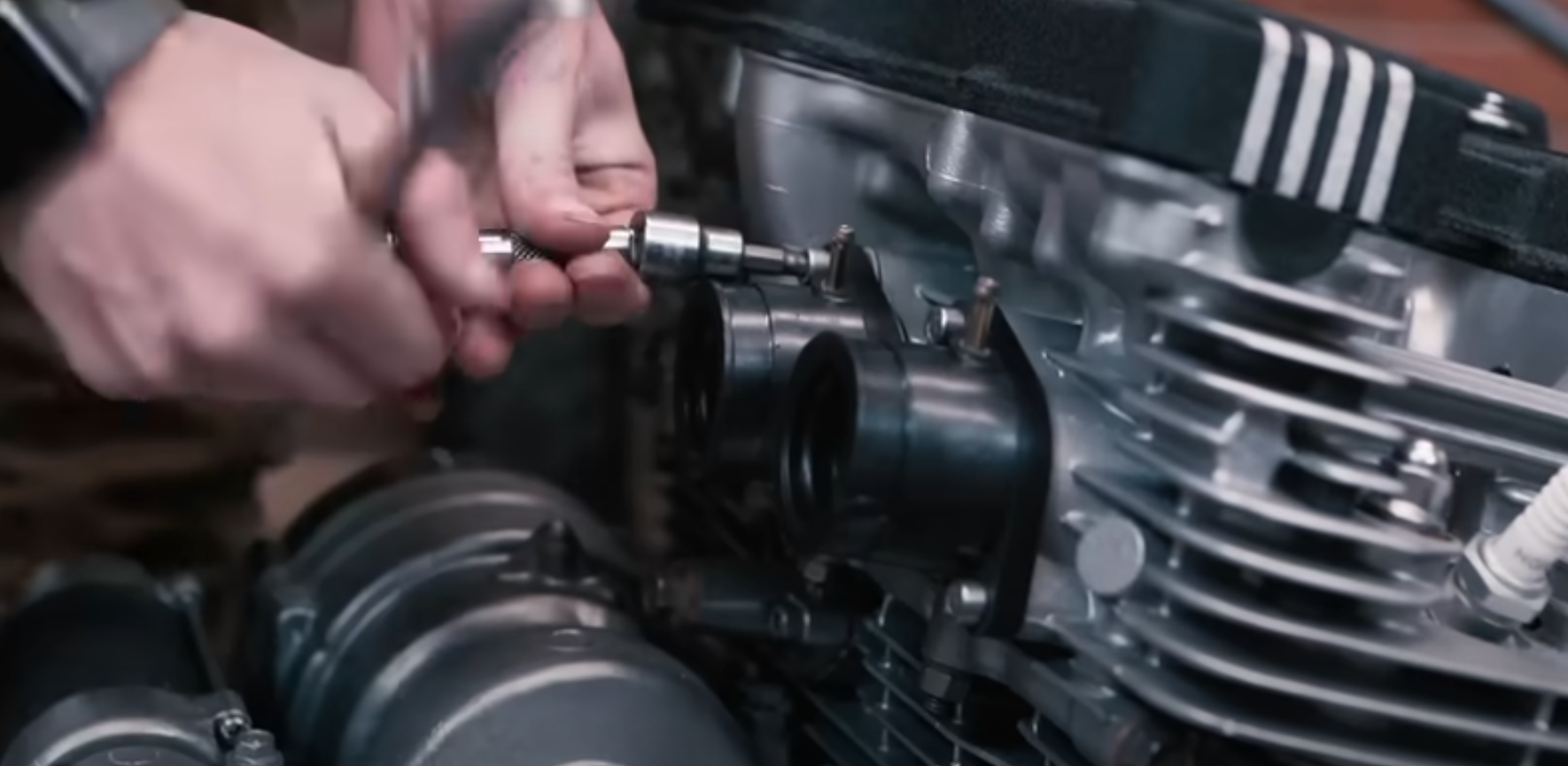

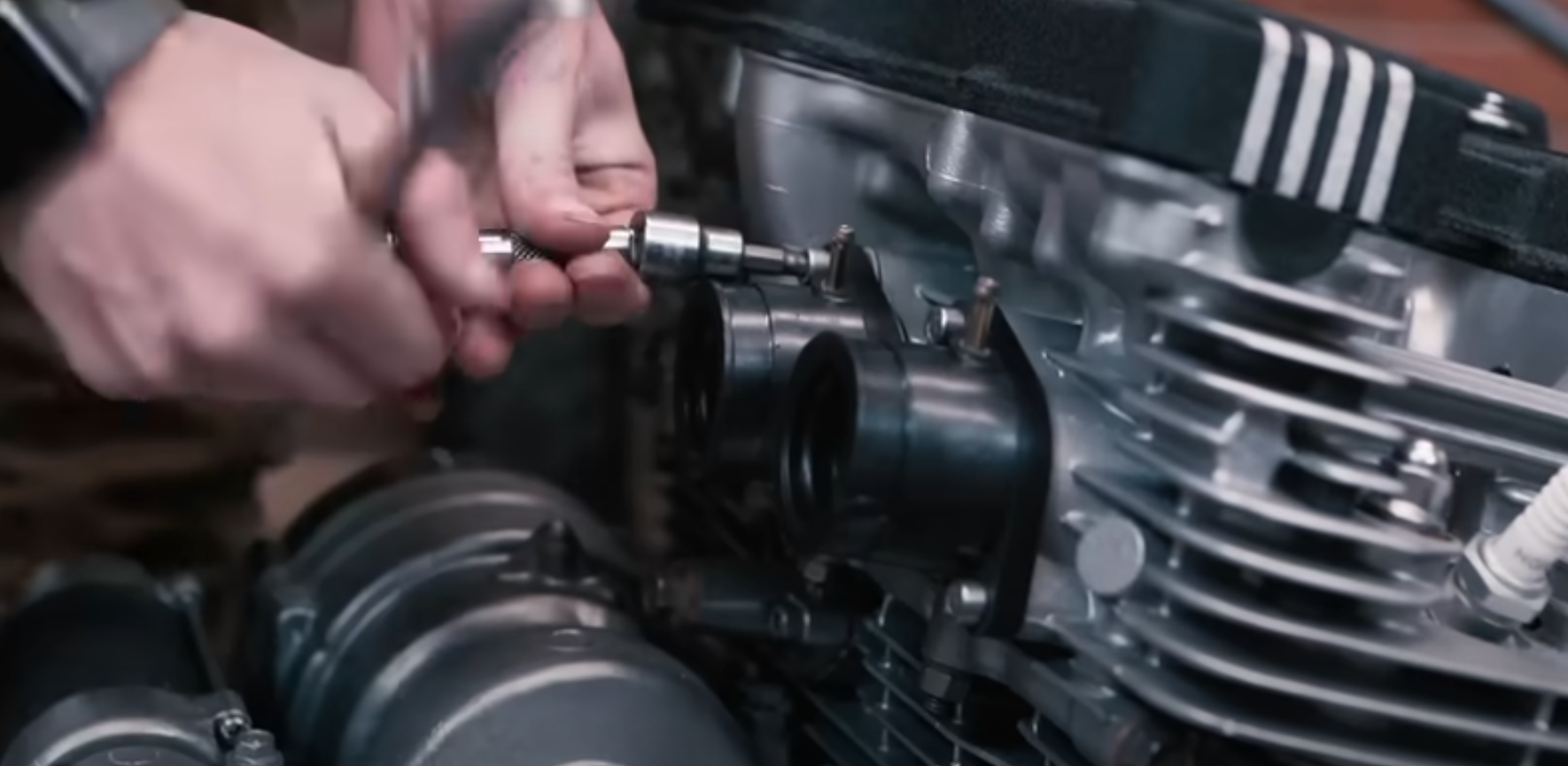

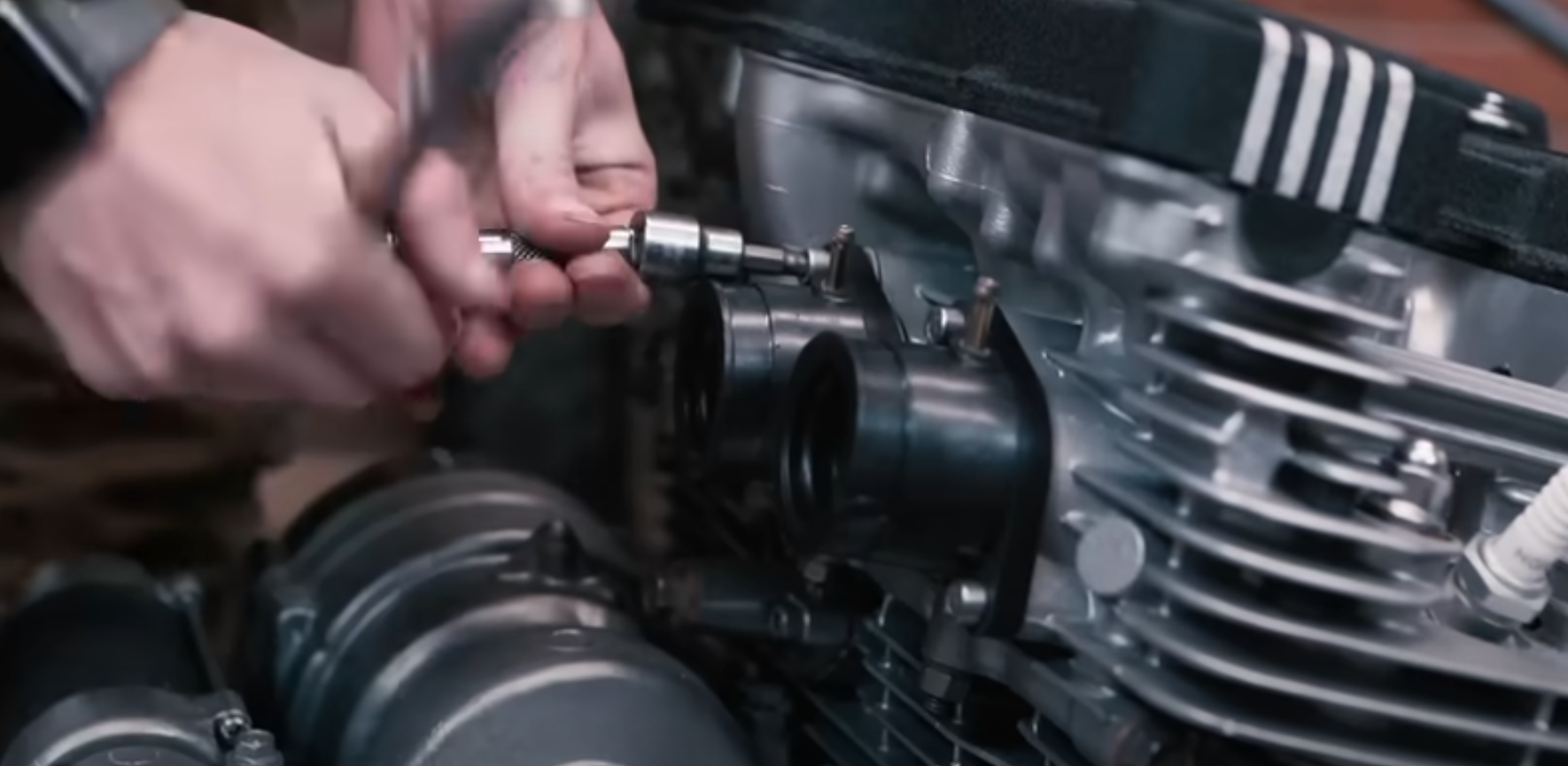

Testing the Engine for the First Time

After altering out the fluids and filters, it was time to see if the engine would begin. The engine fired up and ran nicely. Regardless that it nonetheless wants a tune-up, it labored even after sitting for a very long time. Listening to the engine run once more was a huge second within the construct. It meant the bike was on its method again to the highway.

Word: The engine will want some fine-tuning, however getting it began was a great signal. Seeing the bike come again collectively introduced plenty of pleasure to the mission.

Distinctive Components and Upgrades

Machine-Made Metallic Options

To get the fitting match and form, lots of the metallic elements on the bike had been made with CNC machines. These elements embrace issues like bump stops and different small elements. The usage of CNC lets builders make items which can be each robust and look nice. Every half is measured and lower to suit, serving to the bike really feel contemporary whereas protecting a few of its old-school attraction.

Customized CNC Highlights:

- Precision bump stops

- Hand-finished brackets

- Distinctive match for every half

3D Metallic Printed Tailpipe Ends

As a substitute of utilizing commonplace exhaust ideas, the builder created one-of-a-kind metallic ideas with a 3D printer. This technique lets them check out shapes and types that might be arduous to make by hand. The metallic ideas add a particular contact to the trip and provides the again of the bike a contemporary really feel.

Why 3D Prints Stand Out:

- Distinctive shapes doable

- Clear end on every bit

- Robust, metallic design

| Characteristic | Commonplace Ideas | 3D Printed Ideas |

|---|---|---|

| Customized Shapes | Restricted | Many Choices |

| Manufacturing Pace | Gradual | Quick |

| General Look | Plain | Fashionable |

New Wheels Entrance and Again

An enormous a part of the construct was upgrading each the entrance and rear wheels. The entrance finish was improved first, and the again wheel was made wider to match. This helps the bike look balanced and durable. Every wheel was chosen to provide the trip a contemporary look, whereas nonetheless becoming the remainder of the basic design.

- Wider rear wheel for extra grip

- Chunky tires for a daring look

- Matching types on each ends

Body and Construction Adjustments

Reducing and Welding the Again Finish

The outdated body needed to be modified, so the again half was lower off. A brand new curved piece was made and welded as an alternative. This was the primary time doing a few of these steps, nevertheless it turned out a lot better than anticipated.

Errors occurred alongside the way in which, however attempting once more helped get it proper. The arduous work paid off and seemed good as soon as completed. Customized elements and decisions made this a part of the construct distinctive.

Coating the Body with Powder

After the body was welded and all the additional brackets had been eliminated, it was prepared for powder coating. This course of gave the body a powerful, clear end within the base colour. Seeing the body come again with a contemporary look felt thrilling.

Powder coating made it prepared for the following steps in placing the bike again collectively. The clear body additionally made the engine and different elements look higher as soon as put in.

Standout Construct Options

Tail Mild Concepts from Acrylic

The builder tried one thing new with the tail mild on this bike. As a substitute of utilizing a standard fashion, they used concepts from different builders, like these at Auto Fabrica. They made an acrylic tail mild, however made it in their very own method.

This course of was one thing they hadn’t finished earlier than. They labored arduous to get it proper. When it was completed, the tail mild seemed even higher than anticipated.

- Authentic course of: Impressed by high builders, however designed their very own

- Materials used: Acrylic

- Methodology: Trial and error till it labored

Double Block-Model Headlights

Additionally they wished the entrance to be particular. As a substitute of a single headlight, they selected to make use of two boxy headlights.

It took further work, however the builder preferred how completely different it seemed. Even when some folks don’t just like the fashion, it’s clear that plenty of effort went into making it stand out.

- Kind: Twin sq. headlights

- Cause: To strive one thing few others do

- Outcome: A daring, uncommon search for the entrance of the bike

Detailing and Placing It All Collectively

Small Components and {Hardware}

Paying shut consideration to every nut, bolt, and tiny piece is essential throughout this a part of the mission. Each screw and fastener added makes an enormous distinction in how the bike seems to be and works. This step takes time, however ensuring all the things suits proper is what separates a great construct from an awesome one.

Right here’s a easy guidelines they adopted:

- Sorted all {hardware} by dimension and sort

- Checked every half for rust or injury

- Cleaned or changed outdated nuts and bolts

- Tightened all the things rigorously to keep away from stripping

| Half | Checked? | Cleaned? | Changed? |

|---|---|---|---|

| Engine Bolts | ✓ | ✓ | ✓ |

| Body Fasteners | ✓ | ✓ | x |

| Headlight Mounts | ✓ | ✓ | x |

| Rear Wheel Nuts | ✓ | ✓ | ✓ |

Specializing in these particulars helps the bike not simply look higher but in addition keep robust and secure for driving.

Teamwork and Thanks

Nobody builds a customized bike fully alone. Many alternative folks helped at completely different occasions, giving assist, sharing recommendation, or pitching in with duties. Their assist stored the mission shifting, even when issues acquired powerful or took a very long time.

The builder made certain to thank everybody who helped out. Their names and work are shared on social media, giving them credit score for his or her half within the mission. Every particular person made a distinction, and the bike wouldn’t look the identical with out their assist.

This type of teamwork exhibits how a lot a construct like this will depend on shared expertise and energy. Everybody’s arduous work helped deliver the completed bike collectively.

Wiring System Enhancements

Setting Up the Major Management Field

The builder selected to make use of the M Unit for {the electrical} system. This half is thought for a way easy it makes wiring, even for individuals who don’t take pleasure in this a part of constructing bikes. The bike had been in items for a very long time, so it was an enormous second to get the wiring sorted out.

Key modifications:

- The outdated wiring was changed

- The new M Unit made connecting all the things simpler

- The system is cleaner and fewer crowded

This made the job a lot much less annoying and helped maintain the construct neat and arranged.

Changes and Beginning for the First Time

After organising the wiring, the bike was prepared to start out. It wanted some fundamental tuning and a primary test to see if all the things was working proper. The builder was excited to listen to the engine run once more after all of the updates.

Duties accomplished:

- Ensuring all wires had been related accurately

- Checking the controls to substantiate they labored

- Listening to the engine and making small changes

A desk of checks:

| Process | Standing |

|---|---|

| Wiring full | Sure |

| Engine runs | Sure |

| All controls examined | Sure |

Getting the tuning proper was vital to verify the bike would run easily when it was time to trip.

Ultimate Particulars

Constructing the Seat and Including Upholstery

The customized seat base is constructed to match the fashion of the bike. As soon as the bottom is completed, it goes to an expert upholsterer. Right here, they cowl the seat with new materials for a clear, easy look. This step provides the seat each consolation and a completed fashion.

Seat Particulars:

- Customized-shaped base

- Despatched to upholsterer

- Lined in new materials for consolation

Shaping the Physique and Making use of Colour

After the principle construct, work turns to the physique panels. They’re formed and made prepared for portray. The paint is combined to get simply the fitting colour. As soon as sprayed on, it brings the mission collectively. Brilliant, contemporary paint provides the bike a brand new, completed look.

Steps:

- Form the physique panels

- Prep the floor

- Combine and spray paint

- Let it dry and rebuild the bike

A well-done paint job makes all the things look contemporary and helps shield the bike for the miles forward.

Wrapping Up and Transferring Ahead

Constructing a customized bike means studying each step of the way in which. Every new talent opens up alternative ways to form and repair each half. Errors occur, however so does enchancment. Even when one thing takes just a few tries, it’s all a part of the method.

Subsequent steps within the construct:

- Clear up the smaller elements and test all of the wiring.

- Ship the seat base out for upholstery.

- End the physique work and get the paint finished.

- Put all the things again collectively for the ultimate time.

- Tune the engine earlier than the primary trip.

It takes a group to make a mission like this work. Each particular person concerned has helped make every element higher. The joy grows because the bike nears its first check trip. Updates and extra steps will likely be shared quickly.