At any time when somebody seems at a mannequin airplane, their eyes are drawn to the cockpit. It appears solely pure to count on one thing fascinating inside. Though it could appear daunting to construct an instrument panel, when first beginning out, maintain it easy. You don’t want a lot of a cockpit inside to make it eye-catching.

GETTING STARTED

To make an instrument panel, you solely want three primary elements: First is a backplate of the instrument panel. It will function the world the place the instrument faces will likely be positioned. Second is an instrument panel face. And third are the instrument bezels.

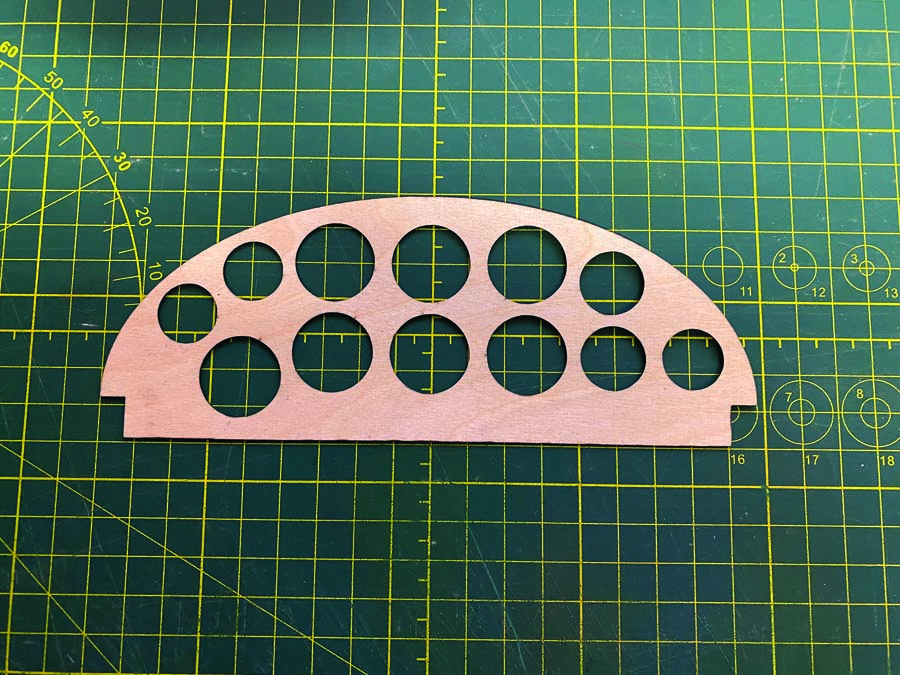

This skinny plywood face has cutouts for the devices.

You may make bezels by slicing inflexible plastic or aluminum tubes, and pinheads of varied sizes can function switches. Your scrap field is a treasure-trove!

Plane like Cessna 172s have primary instrument panels with out quite a lot of bezels.

With bezels, switches, simulated lights, and placards, this instrument panel is able to gown up any ARF!

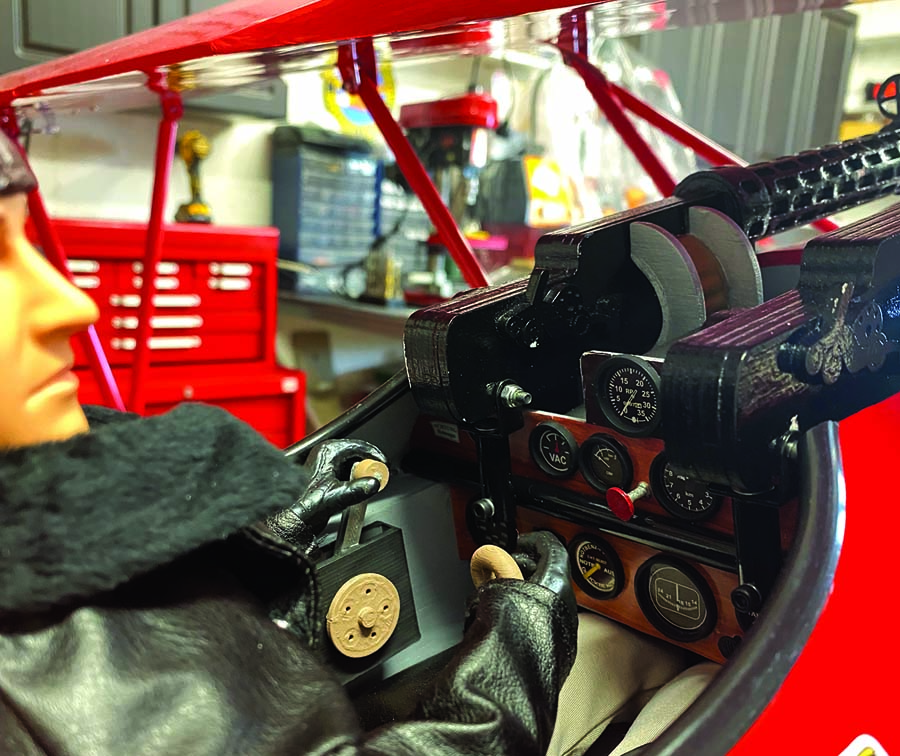

With such a big bubble cover, the instrument panel of the CAP 10 will instantly catch your consideration!

Though bezels have a pleasant impact, they aren’t essentially required in all instances. There are airplanes with instrument panels that don’t present any sort of bezels and as an alternative have a flush look, comparable to a Cessna 172 proven right here. In case you are making an instrument panel for a standoff scale or sport airplane, you may skip including bezels. Nonetheless, in the event you resolve to incorporate bezels, you might have some choices. They are often present in many various sizes from numerous on-line sellers. Or in the event you personal a 3D printer or know somebody who does, bezels may be printed to your necessities. One other method is to make use of aluminum tube and a Dremel cutoff noticed to make them. For those who solely want a couple of, this technique works properly and the load acquire is negligible. If aluminum tube just isn’t accessible, strive utilizing inflexible plastic tube.

As for the instrument faces, there are numerous on-line sources for each type of instrument. Relating to standoff scale or sport fashions, you may select what suits the look you might be after. You’ll be able to copy the picture and resize it in your pc after which it’s merely a matter of slicing and pasting. The instrument faces may also be bought, normally by the identical firm supplying the bezels. I’ve even seen instrument faces that had been lower out of magazines!

PUTTING THE PANEL TOGETHER

STEP 1

The backplate, which is identical dimension and form because the instrument panel, may be created from skinny balsa or cardboard.

STEP 2

For those who printed your personal instrument faces and you might be utilizing them in a standoff scale or sport airplane, I recommend printing them on shiny picture paper to offer the impact of glass over the instrument face. It’s surprisingly efficient. Nonetheless, if you’re in search of extra of a scale look, you may place very skinny self-adhesive plastic movie between the again plate and the panel face.

STEP 3

The instrument panel must be lower out for the instrument faces. This may also function your template to mark the location of the devices on the again plate. The instrument panel face may be created from 1/64-inch-thick birch plywood, which has a really high-quality grain and is simple to complete to acquire a clean steel look. As a result of how skinny it’s, it is rather simple to chop out the instrument cutouts.

Balsa wooden can be utilized and works properly however requires extra ending as a result of its grain. There are numerous methods to make the instrument cutouts on the panel. You could possibly use a laser cutter if accessible. One other technique I’ve used is a brass tube, which is available in many various diameters. Sharpen one finish with a file, and use it as a drill or a punch. Drill bits additionally work, however it may be a problem to realize a really clear lower with that technique.

STEP 4

Now take your instrument panel plate with the cutouts and, utilizing it as a template, draw the place for the instrument faces on the backplate. Then glue your instrument faces to the backplate with a glue stick or Zap cover glue. Use a glue that can permit you to transfer the instrument face to its precise place. Don’t use CA! As a aspect word, the location of flight devices usually has a sample also known as a “six pack.”

Now place the instrument panel face on high of the backplate with the instrument faces whereas making any changes to the instrument faces, making certain every part is aligned. If you end up happy with the look of your panel place and instrument faces, glue on the panel. I take advantage of a 5-minute epoxy so I’ve time to line up the panel precisely the best way I would like it.

For those who like, apply miniature screws to the panel to offer a practical look, as that’s how actual devices are connected in airplanes. I’ve purchased miniature screws from a mannequin railroad store and numerous distributors that promote cockpit elements. To put in the screws, merely drill the suitable dimension holes and push the screws into the holes (don’t screw them in). I take advantage of a small hand drill to make the holes and drill proper via the backplate. Don’t attempt to glue the screws when putting them within the holes. When all of the screws are in place, flip the panel over to the again aspect and you will notice the holes you drilled for them. Now you can use medium CA glue and put a small drop on each screw gap. For those who attempt to glue the screws from the entrance panel aspect, you danger getting glue on the panel. I communicate from expertise!

When you might have decided what you need your panel to appear to be to go well with the plane you might be constructing, it’s time to set up switches and lights. You probably have entry to a 3D printer, you might print the mandatory elements, or you should buy them from numerous distributors. You might also be capable to discover a few of these elements proper in your store by in search of small gadgets that resemble one thing you may even see on an instrument panel. For instance, in my World Struggle 1 airplane, I made some elements from small items of scraps that I by no means throw out, comparable to brass tube, and so on.

To complete detailing the panel, you’ll want to use the suitable labels and placards. Utilizing a phrase processor in your pc, you can also make numerous dimension labels. Then use shiny or satin end picture paper to print the labels. When making use of the switches, lights or labels, I take advantage of a toothpick to exactly management the appliance of glue and use as little glue as potential.

Now you can set up your accomplished panel within the airplane and admire the transformation of the mannequin. Don’t overlook the pilot! The airplane seems unusual being flown by a ghost! For extra ideas and strategies on creating and putting in instrument panels, see my video at ModelAirplaneNews.com/panel.

Standoff scale Fokker Dr1 cockpit added.

A number of elements are bits and items of scrap materials reworked into cockpit elements.

Hangar 9 Fokker D-Vll cockpit reworked from a decal instrument panel and shoulder pilot to one thing slightly extra reasonable with added bezels, elements, and a full-body pilot from Warbird Pilots.

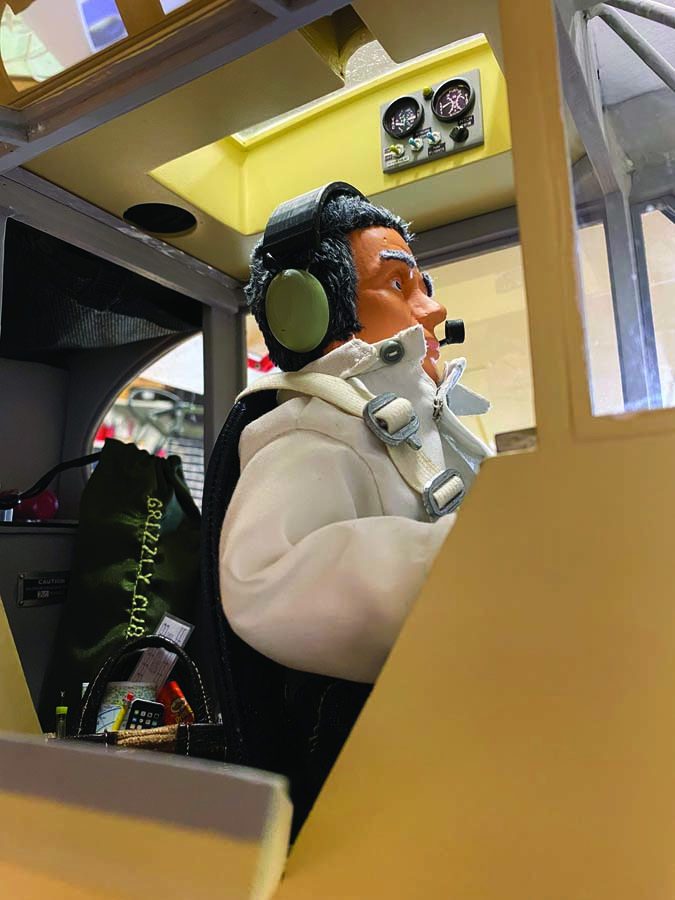

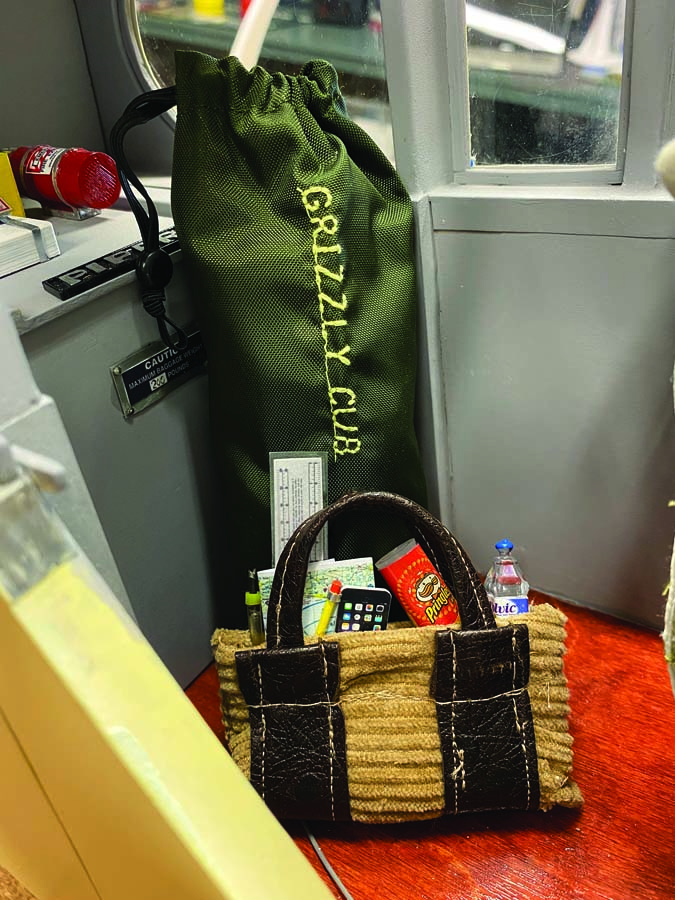

Contained in the Grizzly Cub

This 1/4-scale Cub has been modified to resemble a custom-made Tremendous Cub. I constructed it utilizing Sig Cub plans. The mannequin is roofed with Koverall material, has a lighting system and is powered by a DLE 35 engine with an electrical begin. This cockpit has no indicators of any radio gear, it’s all hidden. I even put in a headliner to cover the servo and lighting wires to the wing. I additionally scratch-built the pilot out of 3D-printed elements and a sewn-up physique.

ABOUT THE AUTHOR

Rick Hanus developed a eager curiosity in plane modelling on the early age of 11, transitioning from U-control to RC plane. His ardour for airplanes impressed him to pursue a profession in aviation, the place he held numerous positions inside the business. He retired as an airline pilot after serving in quite a few capacities, together with teacher and fleet Chief Pilot for a serious airline.

Textual content & Pictures By Rick Hanus