Maybe that is what occurs once you’ve been working in snowboarding lengthy sufficient to see traits come and go. Earlier than he based Amplid, again in 2004, Bauer had a 20-year profession as a pro-rider. He first stepped on a board again in 1984, obtained sponsored by Burton in 1986, and went on to win 5 European Championships, 4 World Championships, and an unimaginable 84 World Cup occasions.

“It’s humorous now, as a result of carving is cool once more”

Whilst a professional, he resolutely refused to leap on bandwagons. Bauer was a succesful freestyle rider with a good bag of methods, together with a imply technique. However though he competed within the halfpipe (slopestyle didn’t exist again then) and grew to become vice world champion within the “mixed disciplines” behind Craig Kelly, he began to deal with racing after a number of seasons, a self-discipline that grew to become much less and fewer trendy because the 90s wore on—and on perfecting his carve. “It’s humorous now, as a result of carving is cool once more,” Bauer says—whereas again within the day, he remembers different snowboarders utilizing homophobic slurs to explain him and his fellow racers. “Even the verb ‘carving’ was banned,” he says, laughing on the ludicrous lengths the game’s self-appointed gatekeepers went to. “You couldn’t even say ‘I’m simply going to carve some turns,’ it was in opposition to snowboarding sharia, you’d have been stoned instantly.”

Not that any of this stopped him having a protracted and profitable profession, or from growing an in depth working relationship with Jake Burton. Over time, Bauer grew to become more and more concerned in his sponsor and mentor’s design course of, serving to him good most of the fashions that outlined Burton’s vary within the late 90s. When it got here time to hold up his boots, he knew he wished to begin his personal snowboard firm. However as along with his driving profession nevertheless, he knew that he wished to do issues in another way.

“The intention was to make a greater experience, fairly than a louder model.”

A Materials Distinction

A fast Snowboard Manufacturing 101: Most snowboards, each then and now, are produced in only a handful of factories around the globe. Many of those provide inventory supplies, shapes and designs, and sometimes, the most important distinction between totally different firms’ boards are the graphics. The truth is, Bauer says, “Anybody can go to any manufacturing facility and go, ‘Okay, listed here are my graphics, I want to place an order of 100 objects per size, for 300 or 400 boards or no matter,’ after which you’ve your snowboard model.”

Slightly than think about the product itself, firms usually spend the majority of their money and time on model constructing. “With out mentioning any names, there’s quite a lot of manufacturers who selected the route of promoting, of shopping for world champions, paying quite a lot of riders, and investing into film manufacturing—however really, they’ve a mediocre product,” Bauer explains. “Whereas with Amplid, we selected to speculate our major income into R&D, into moulds, and into experimenting with new supplies”. From the beginning, he says the intention was “to make a greater experience, fairly than a louder model.”

Amplid’s present line-up of boards, no-one would ever accuse them of being loud. Even at their most vibrant, their graphics solely characteristic a number of muted pastels. Beneath the understated topsheets, nevertheless, there’s a complete lot happening. Take the Centrifugal Assortment, for instance: three fashions, the Souly Grail, the Time Machine and the UNW8, designed for high-speed carving each on piste and in powder. “We wished to make actually responsive boards which might be a bit simpler longitudinally,” Bauer says. Your basic hard-charging board “is tremendous responsive, and stiff, however then after two runs it’s so fatiguing—not simply in your thighs but in addition in your nerves since you’re all the time making an attempt to, like, not kill this Dutch skier in entrance of you,” he laughs.”

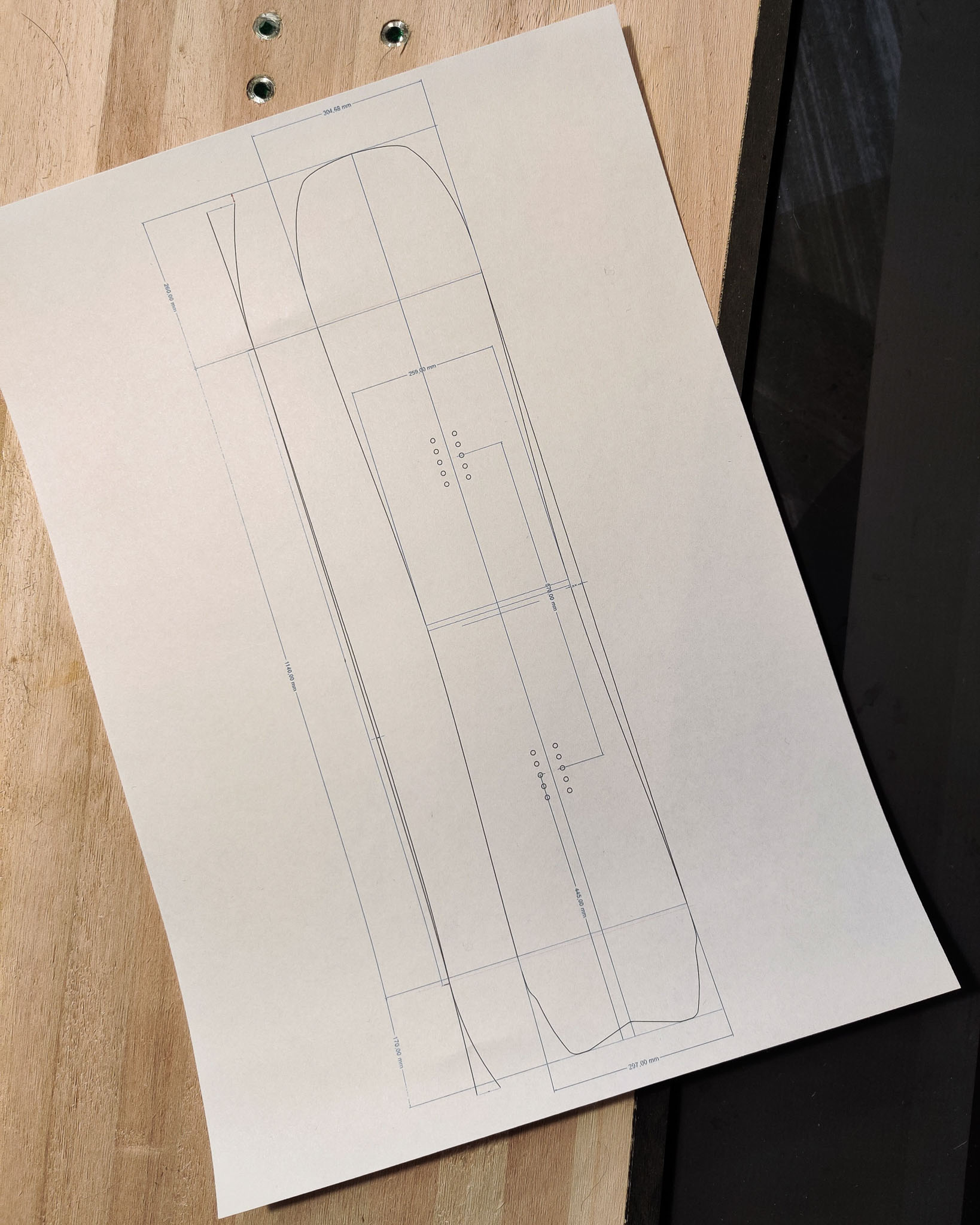

Considering exterior the field, he experimented with arranging carbon stringers, which historically run nostril to tail on a snowboard, at a 90 diploma angle from edge to edge. “I actually like carbon, however I don’t like carbon within the longitudinal axis,” he explains. “This manner, once you’re on an edge you’re feeling it. We will profit somewhat bit from the torsional rigidity of carbon, however on the longitudinal flexibility you’ve this straightforward, glass fibre flex, which you need.” Bauer’s want to experiment with supplies has taken him to some stranger locations too. “There are these actually nerdy boards on the web the place individuals focus on the properties of composite. Then there are composite commerce reveals you’ll be able to go to,” he says. “Ninety-nine p.c of what you see is ineffective, however then you definitely see one thing and also you assume ‘huh, this might work in a snowboard.’”

It was an opportunity discover like this that led to one in all Amplid’s most radical design improvements to this point: “The Hole Challenge,” a board with no wooden core in any way. “We discovered this honeycomb materials made in Germany,” Bauer says, “and we wished to see how mild we might go along with a board. The burden was insane, on the chairlift it felt such as you’d dropped your board,” he says. They seemed cool too. Bauer holds up his cellphone torch and reveals me how one can see the sunshine by means of the snowboard. However the flex didn’t really feel nice in any respect, so utterly hole boards by no means made it previous the prototype stage.

“R&D is all the time two steps ahead, one step again,” Bauer says. And the trial and error course of led to Amplid utilizing the honeycomb materials on the nostril and tail of numerous their present vary. “That’s the place it actually is sensible, on the tip and tail,” Bauer says. Freestyle boards that includes this “hole tech” have massively lowered swing weight, which is nice for spinning, he says. And hole tech additionally options of their best-selling Milligram splitboard—one of many lightest ever produced.

“Today there’s no such factor as a very dangerous board … however there are a lot of boring boards.”

Constructing Boards with Character

A few of this may sound like tinkering for tinkering’s sake, however there’s all the time a objective. As board manufacturing has grow to be extra standardized through the years, requirements have risen. Today there’s no such factor as a very dangerous board, Bauer says, however there are a lot of boring boards. And from day one, Amplid’s mission, as he sees it, has been “to construct boards with character.”

This even applies to their all-mountain boards. Though many manufacturers don’t prefer to admit it, any board that’s a jack of all trades should, logically, make compromises. “There are all the time sure sacrifices,” Bauer explains, “like do you need to compromise on efficiency in powder, or possibly within the park?” This may end up in actually boring boards that don’t do something significantly nicely. However by accepting the necessity to compromise, and by “allocating and defining precisely the place these compromises are,” Amplid have managed to provide The Singular, an all mountain mannequin that also feels distinctive and enjoyable. “For my part, and naturally that is utterly absent of objectivity, it’s the all mountain board with the least sacrifices,” Bauer says.

If The Singular feels singularly totally different, their extra clearly distinctive fashions are much more characterful. Take the Kodama, a splitboard constructed particularly for Japow-style tree strains (it’s identify means “tree spirit” in Japanese) which has a stubby swallow tail, an enormous spoonlike nostril, and solely is available in a relatively brief 156cm. Or The Snomelier, made for connoisseurs of high-alpine backcountry strains. The Temper Bender, designed as “the perfect backcountry and sidehit freestyle board,” which blends a twin flex with a tapered form is one other instance.

In fact, Amplid aren’t alone in experimenting with unusual shapes. Over the previous 15 years, there’s been an explosion within the variety of bizarre and wonderful-looking snowboards available on the market. The pattern was taken to its logical excessive by the Helgason brothers, who in sometimes pisstaking fashion, launched a board known as the Lobster Nosejob in 2013 which inspired homeowners to carve their very own shapes out of every finish. However Amplid’s form and design decisions are greater than beauty—they actually make a distinction to how every board feels and rides.

Precision Tech & Terminology

Bauer says he finds quite a lot of the chat round form a bit woolly. “Folks speak rather a lot about shaping boards, like they’re surf boards. Nevertheless it’s a totally totally different course of. Shaping a surfboard is a extremely revered craft—it’s a mixture of really feel and spirit and understanding the surfer you’re shaping for. It’s arms on, you get your arms soiled. Whereas you don’t form a snowboard. You’ll be able to lay it up by hand, certain, but it surely goes in a press.” Nevertheless romantic it would sound, Bauer says he might by no means truthfully describe himself as a shaper. “I’m a designer and a producer.”

“There are different terminologies that actually piss me off too as a result of they’re bodily incorrect,” he says. It’s now frequent to speak of brief fats snowboards—like Amplid’s Kodama cut up, for instance—as “quantity shift” boards, one other time period lifted from browsing. “However that’s clearly so incorrect,” Bauer says. “Quantity doesn’t matter in a snowboard—even in the event you make it 5 occasions thicker, you’re not going to drift higher in powder. It’s all about floor space. So what we ought to be calling them is ‘surface-shifted’ boards.”

In fact Bauer’s been round lengthy sufficient to know that advertising usually wins out. If surf phrases like “quantity shift” assist shift massive volumes of boards, manufacturers will maintain utilizing them regardless. “That is possibly additionally a purpose why we’re not enormous,” he says. Amplid won’t ever be a mass-market model, he says, “as a result of we go our personal approach.” However Bauer is proud that they’ve grown constantly all through the previous 20 years, and their boards encourage fierce loyalty of their followers. And it’s clear that for Bauer, precision issues, when it comes to terminology in addition to tech. At one stage in our chat I ask whether or not Amplid’s HQ is on the German or the Austrian facet of the border. “Neither, we’re on the Bavarian facet,” he says laughing. The remark is supposed as a joke, but it surely’s a revealing one, suggesting not simply pleasure in his fiercely-independent dwelling area, but in addition his exact engineer’s mindset.

Bavaria is, after all, globally famend for its precision engineering. BMW, Mercedes, and Audi, all hail from the world. It could be tempting to recommend that Amplid, whose modern, high-end boards ooze a Vorsprung durch Technik vibe, share some DNA with these automotive giants. However the fact might be less complicated. They’re the results of years of laborious graft and centered R&D work, led by a single-minded particular person who’s by no means been swayed by traits. “And this,” Bauer says, “is why our boards look totally different, and really feel totally different, and experience totally different.”

This winter we reviewed the Amplid Soulmate and awarded it among the best All-Mountain Snowboards available on the market. Test our full assessment under: