Constructing a customized motorbike half from uncooked supplies takes persistence, planning, and a spotlight to element. The method typically begins with easy design work, testing concepts on cardboard earlier than shifting to stronger supplies. From there, patterns are refined, measurements are marked, and the metallic is formed step-by-step till the specified kind begins to take form.

Workshop setup additionally performs a key function. Utilizing cell gear, choosing the proper thickness of metal, and counting on each hand instruments and machines assist maintain the work environment friendly and exact. Every stage, from forming the wire body to ending the seat base, provides as much as a venture that’s each practical and well-crafted.

Key Takeaways

- Cautious design and planning information every step of the construct

- The proper instruments and supplies enhance accuracy and effectivity

- Small changes throughout shaping result in a greater remaining end result

Designing the Cafe Racer Cowl

Utilizing Cardboard Mockups

He started the method by shaping the design with cardboard. This step allowed him to check totally different outlines earlier than committing to metallic. A number of variations had been typically made till one appeared proper.

Advantages of cardboard mockups:

- Fast to chop and alter

- Low price earlier than shifting to metal

- Helps visualize proportions on the bike

| Materials | Function |

|---|---|

| Cardboard | Check design shapes |

| Paper | Mark shrink factors |

| Metal rod | Construct wire buck for symmetry |

Pause and Replicate Method

He typically relied on what he known as the pause and mirror technique. This meant sitting again, trying on the work, and considering by way of modifications earlier than shifting ahead.

This step was much less about instruments and extra about persistence. By taking time to review the form, he might spot uneven areas or design flaws early.

Key factors of this technique:

- Step away from the venture to reset perspective

- Search for symmetry and steadiness

- Keep away from speeding into the subsequent stage

Materials and Device Selections

Deciding on Sheet Metal

He labored with cold-rolled gentle metal in several gauges to form the cowl. At first, he used 18 gauge (1.1 mm), which proved too heavy for the venture. He then switched to 20 gauge (0.95 mm), discovering it robust sufficient whereas simpler to kind.

| Gauge | Thickness | Notes |

|---|---|---|

| 18 | 1.1 mm | Very robust, however heavy and more durable to form |

| 20 | 0.95 mm | Lighter, simpler to work, nonetheless sturdy |

He lower templates from paper to information the place shrinking was wanted, then transferred these marks onto the metal earlier than shaping.

Warmth-Shaped Plastic for Seat Pans

For the seat base, he used a thermoplastic sheet that softens with warmth and shapes on to the motorbike body. As soon as cooled, it turns into inflexible and will be lower and sanded like wooden.

- Benefits:

- Conforms completely to the bike

- Simple to chop, sand, and end

- May be paired with seat clips for knowledgeable match

This alternative simplified the method of constructing a exact and sturdy seat basis.

Key Instruments for Shaping Steel

He relied on a mixture of powered and hand instruments to kind the sheet metallic.

Fundamental instruments:

- Nylon hammer

- Sandbag

- Heart punch for marking reference factors

Shaping and ending instruments:

- Energy hammer with retractable wheels for mobility

- Shrinker-stretcher for adjusting edges

- Bead curler to spherical seatpan edges

- English wheel or planishing hammer for smoothing

For these beginning out, a shrinking stump, nylon hammer, and sandbag can deal with many of the work with out superior machines. Even easy hand planishing towards a dolly or mounted floor can obtain clear outcomes with sufficient effort and time.

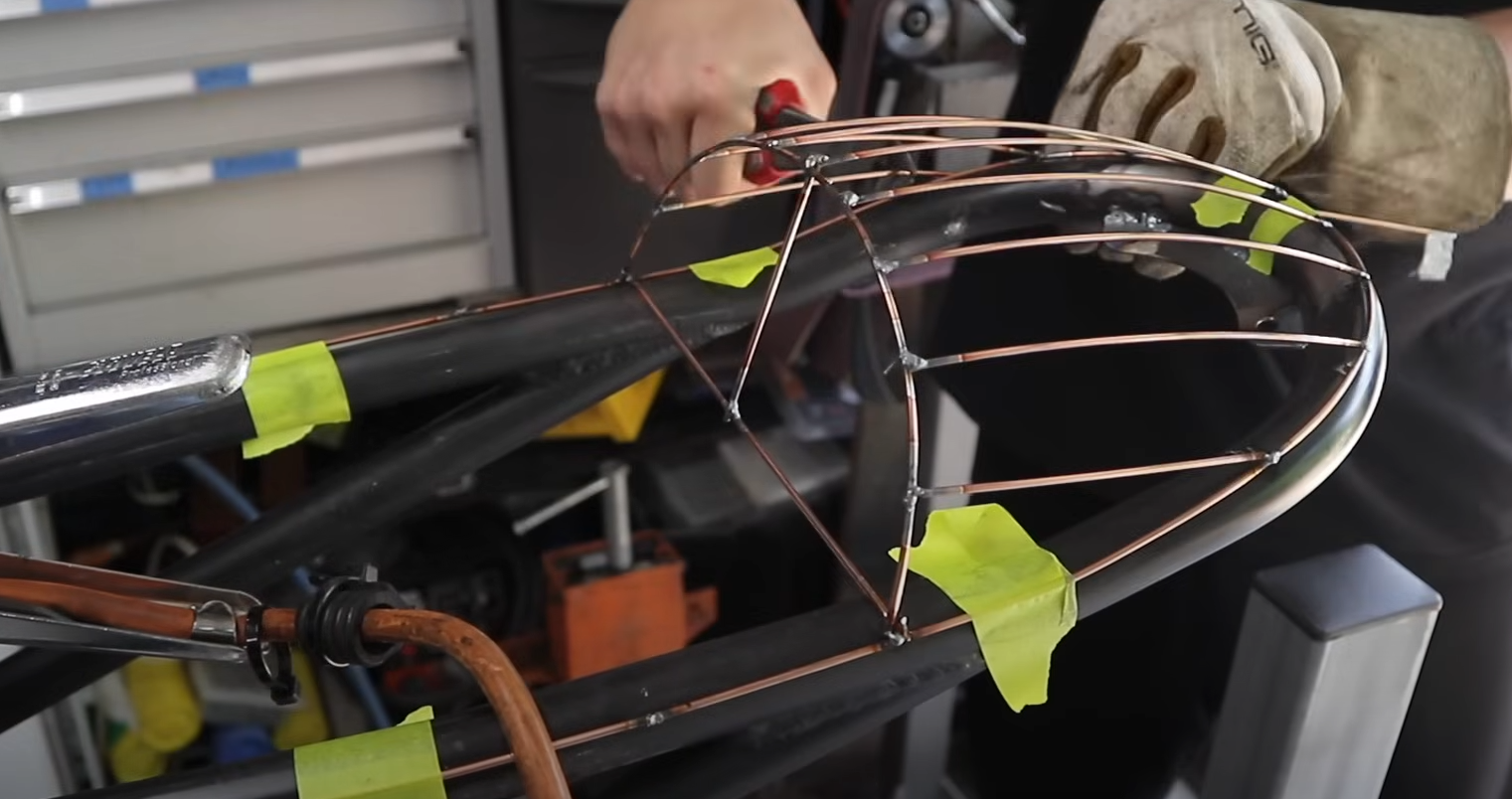

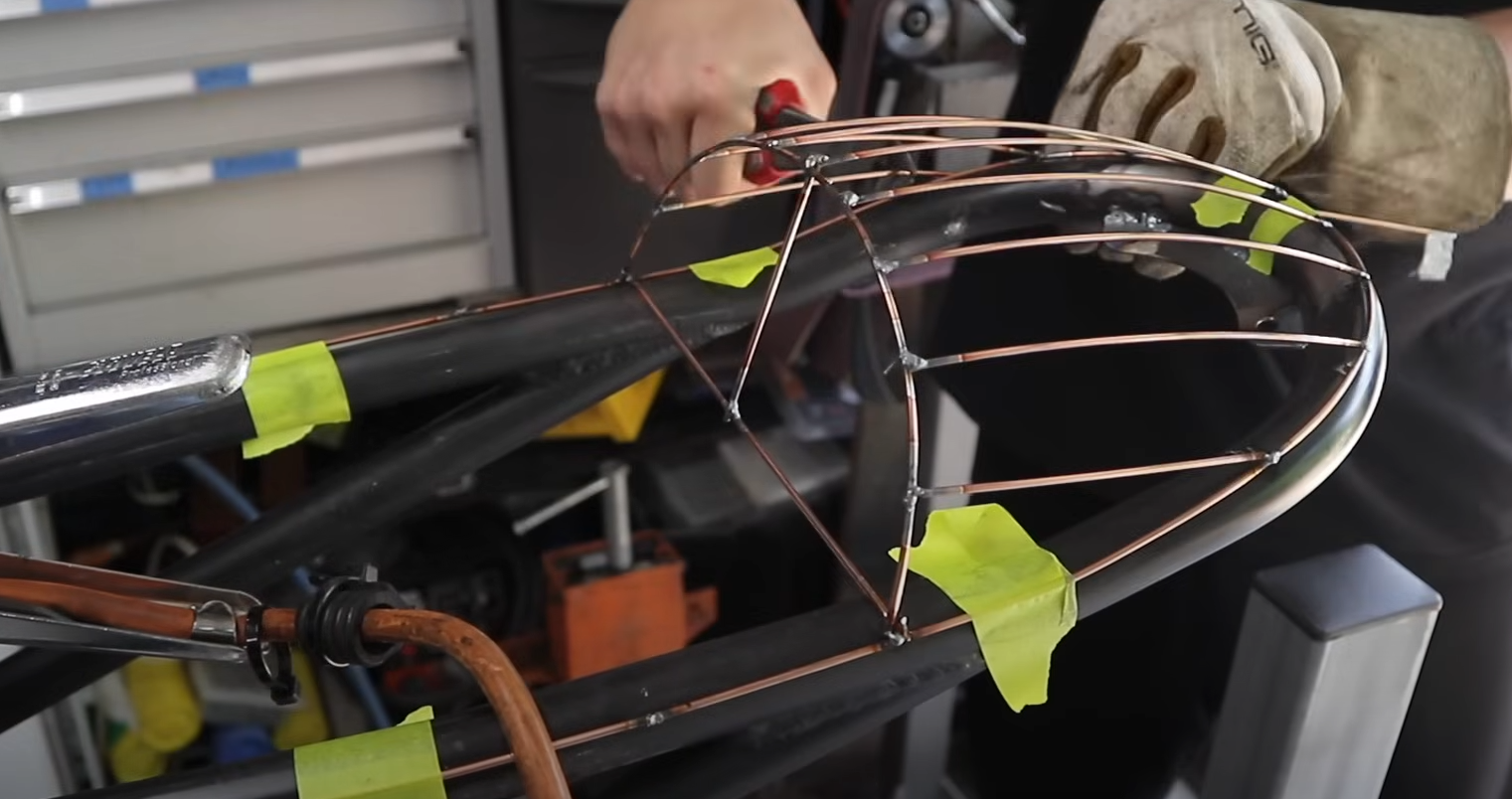

Forming the Wire Body

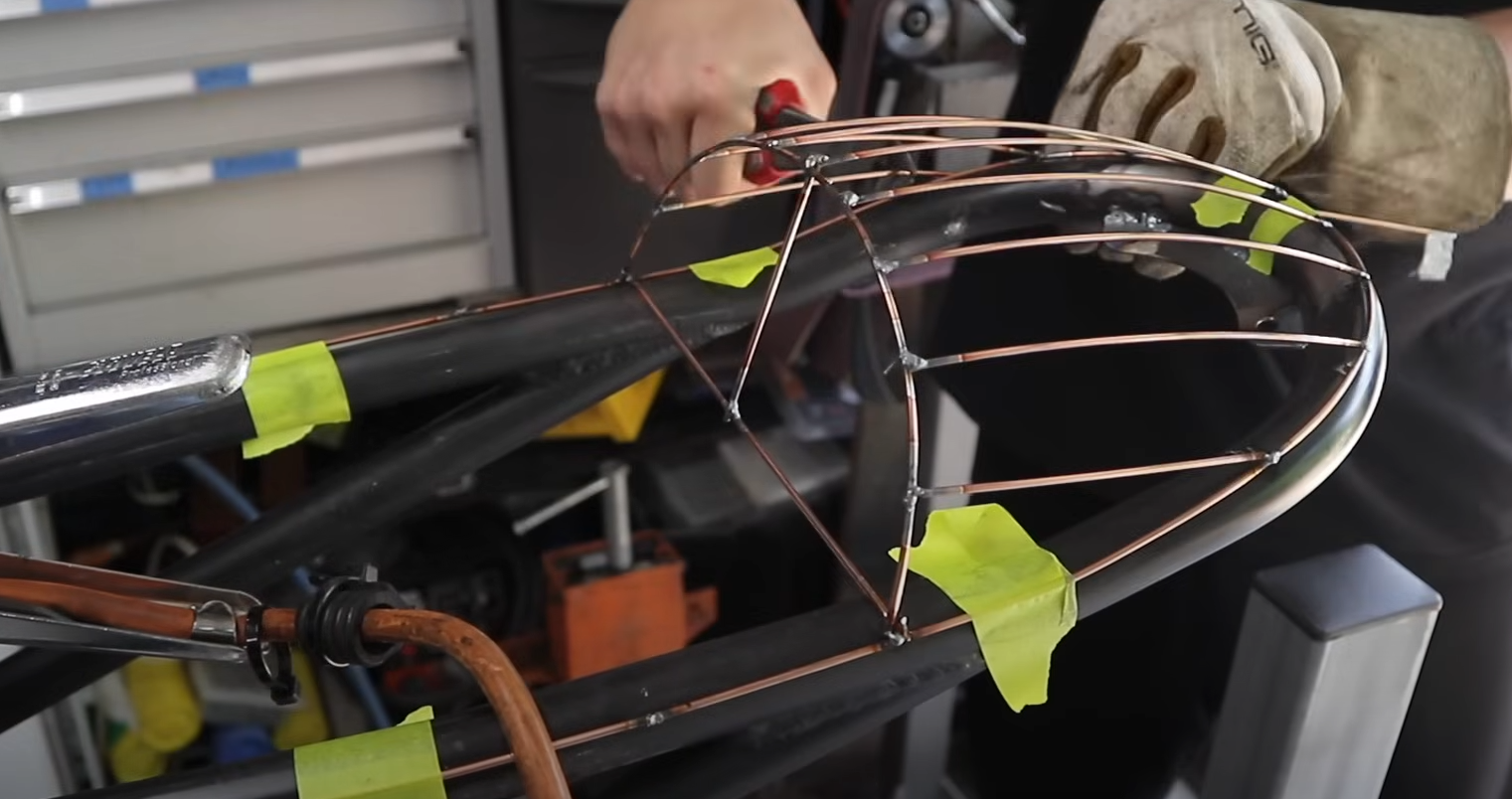

Working with Metal Rods

He formed the body utilizing 2.4 mm metal rods usually used for TIG welding. These rods labored effectively as a result of they had been straightforward to chop, bend, and alter. As every bit was added, the body confirmed the place the curves lined up evenly, which made it simpler to identify areas that wanted correction.

Key factors:

- Materials: 2.4 mm TIG filler rod

- Function: varieties the bottom form of the hump

- Profit: straightforward to chop, bend, and alter for accuracy

Retaining Each Sides Even

He targeted on ensuring either side matched by checking the form as he constructed it. The wire body helped reveal any excessive or low spots, which he might then alter till the curves appeared balanced. This step ensured that the ultimate metallic piece would sit evenly as soon as it was fashioned.

Easy checks for steadiness:

- Evaluate left and proper curves typically.

- Regulate rods till either side match.

- Use the body as a information earlier than shifting on to paper templates.

Transferring Patterns and Setting Reference Marks

Utilizing Paper Patterns

After shaping the wire body, he moved on to paper to map out the design. The paper helped determine the place the metallic would wish shrinking. He folded the paper wherever the floor would pull in, creating clear guides for later shaping.

To maintain monitor of those changes, he outlined the areas instantly on the paper. This step ensured that after the metal was lower, the shrinking course of might observe the identical mapped factors.

Key steps he adopted:

- Hint the wire body onto paper

- Fold paper at shrinking factors

- Mark areas that want shaping earlier than slicing metal

Marking with a Punch Device

Since marker traces can fade throughout shaping, he used a punch to create small, everlasting dots within the metal. These marks acted as reference factors that stayed seen by way of hammering and forming.

This technique allowed him to return to the precise spots that wanted consideration, even after a number of rounds of shaping. It additionally gave consistency when evaluating either side of the piece.

| Device | Function |

|---|---|

| Marker | Fast format, short-term information |

| Punch | Everlasting reference marks |

By combining each marking strategies, he saved the method correct and prevented shedding monitor of the important thing shrinking factors.

Steel Shaping Strategies

Decreasing and Increasing Steel

He marked the sheet with small punch marks to trace the place the metal wanted shrinking. By controlling these areas, he might pull the metallic in and create the curves wanted for the cowl. When the metallic stretched too far, he switched to a stretcher instrument to convey it again into form.

Instruments used:

- Shrinker/Stretcher

- Heart punch for reference factors

- Marker for format

Working with a Energy Hammer

The energy hammer sped up the shaping course of by rapidly shrinking and forming the metal. He mounted the machine on retractable wheels so it might transfer across the workshop however keep steady throughout use. A couple of minutes of hammering gave the piece its tough form, which he then refined with hand instruments.

Benefits:

Hand Ending Strategies

He confirmed that shaping may be achieved by hand with easy instruments like a nylon hammer, sandbag, or perhaps a dolly. By putting towards a stable floor, he flattened and smoothed out excessive spots. Though slower than machines, this technique nonetheless produced correct outcomes.

Fundamental hand instruments:

- Nylon hammer

- Sandbag

- Dolly or stable floor

Utilizing an English Wheel

For remaining smoothing, he turned to the English wheel. This instrument eliminated small imperfections and gave the metallic a clear, even floor. Smaller wheels labored greatest for motorbike components, and he famous they had been inexpensive for anybody eager to do extra initiatives.

Key advantages:

- Smooths out hammer marks

- Creates even curves

- Works effectively for ending skinny sheet metallic

Workshop Effectivity and Mobility

Wheel Upgrades and Retractable Design

He positioned practically each machine in his workshop on wheels to make shifting gear simpler. The hydraulic raise desk obtained upgraded casters, which improved dealing with and stability. The facility hammer additionally sits on a wheeled base, however with a retractable system so it stays regular throughout use and may nonetheless be rolled out of the best way when wanted.

Machines on Wheels:

- Hydraulic raise desk (with upgraded wheels)

- Energy hammer (with retractable setup)

- Most different workshop instruments, besides the metallic lathe

This setup permits him to regulate the format rapidly, creating more room when required. The retractable design prevents heavy gear from shifting whereas in operation.

Device Storage and Setup

Retaining instruments organized helps him work sooner and keep away from wasted time. He typically depends on easy storage options that maintain hammers, markers, and shaping instruments inside attain.

Generally Used Instruments:

| Device | Function |

|---|---|

| Nylon hammer | Shaping and stretching metallic |

| Sandbag | Backing for hammer work |

| Shrinker/Stretcher | Adjusting seat base fitment |

| Bead curler | Rounding and strengthening edges |

By arranging the workshop with mobility and group in thoughts, he maintains a clear, adaptable area that helps each small changes and bigger fabrication initiatives.

Seat Base Fabrication

Marking the Body Heart

He situated the center of the motorbike subframe to make sure the seat base would sit evenly. This step gave him a transparent reference level, which helped maintain the general match correct. With out this, the seat might shift to at least one aspect or sit erratically.

Rolling the Seatpan Edges

He used a bead curler to curve the sides of the seatpan. This step helped the panel match extra snugly towards the bike. Nonetheless, rolling the sides additionally precipitated the panel to flatten barely, which required additional adjustment.

Instruments Used:

- Bead curler

- Reduce metal seatpan

Adjusting with Shrinker and Stretcher

He corrected the flattened areas by working with a shrinker and stretcher. When the changes went too far in a single route, he swapped the tooling to stretch the panel again into place. This back-and-forth course of allowed him to refine the form till the seatpan matched the body.

Adjustment Course of:

- Shrink edges the place wanted

- Stretch areas that pulled in too far

- Repeat till alignment matched the body

Closing Construct and Ending Particulars

Strengthening the Entrance Lip

He tipped the entrance fringe of the seat base earlier than attaching the hump. This step added additional power to the panel and in addition gave it a cleaner, extra skilled look. By folding the sting barely, the piece held its form higher and resisted flexing.

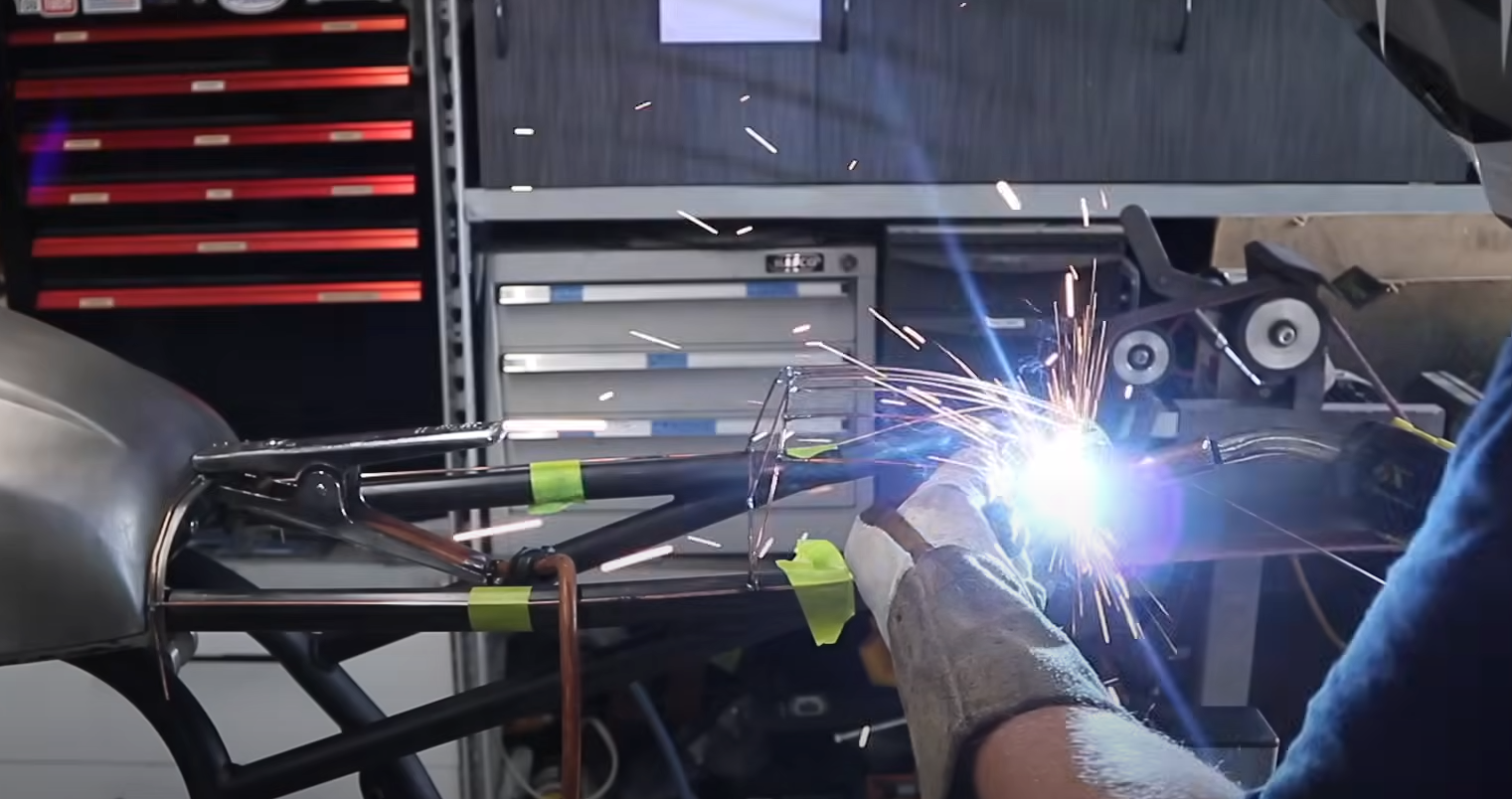

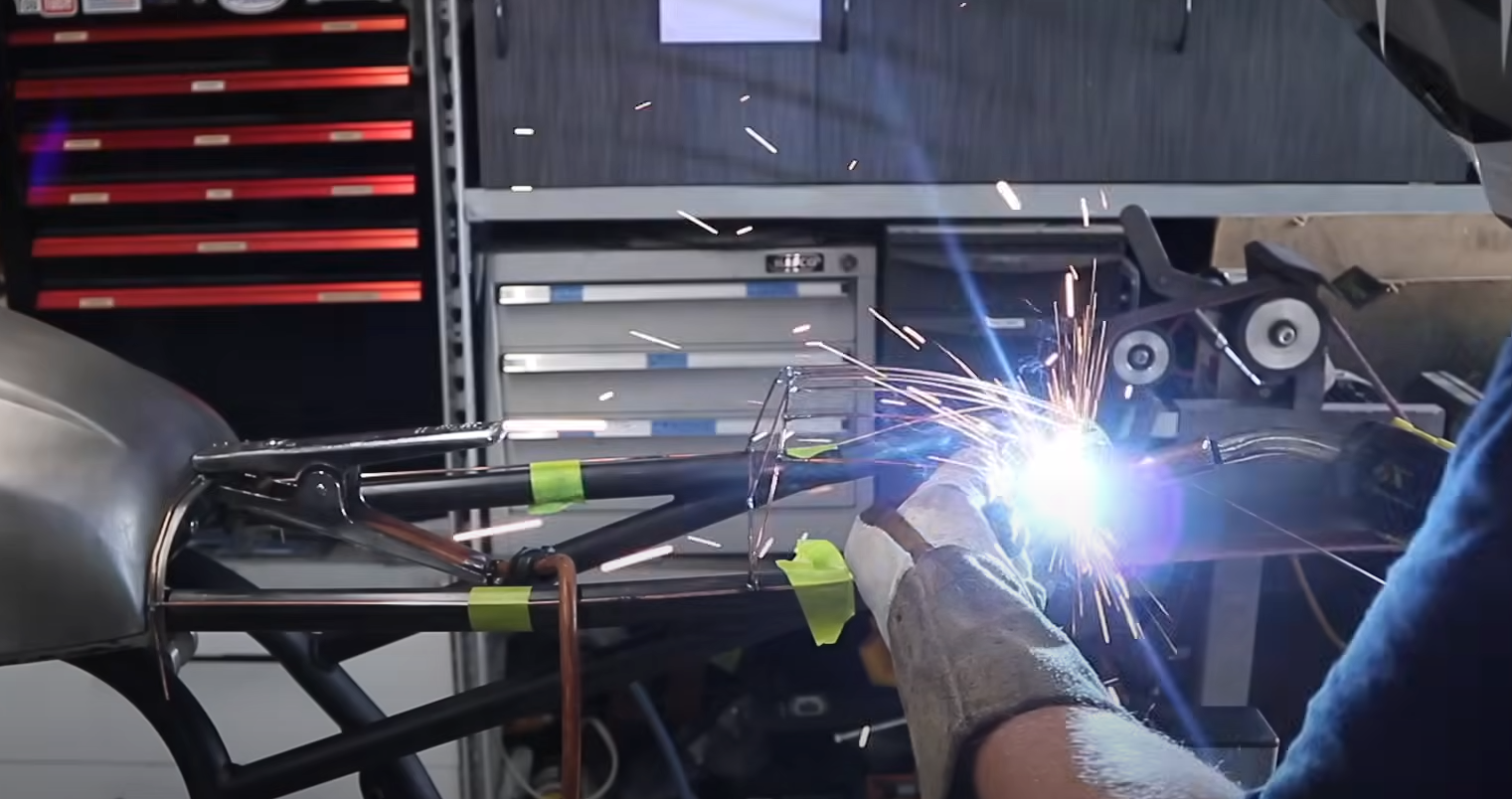

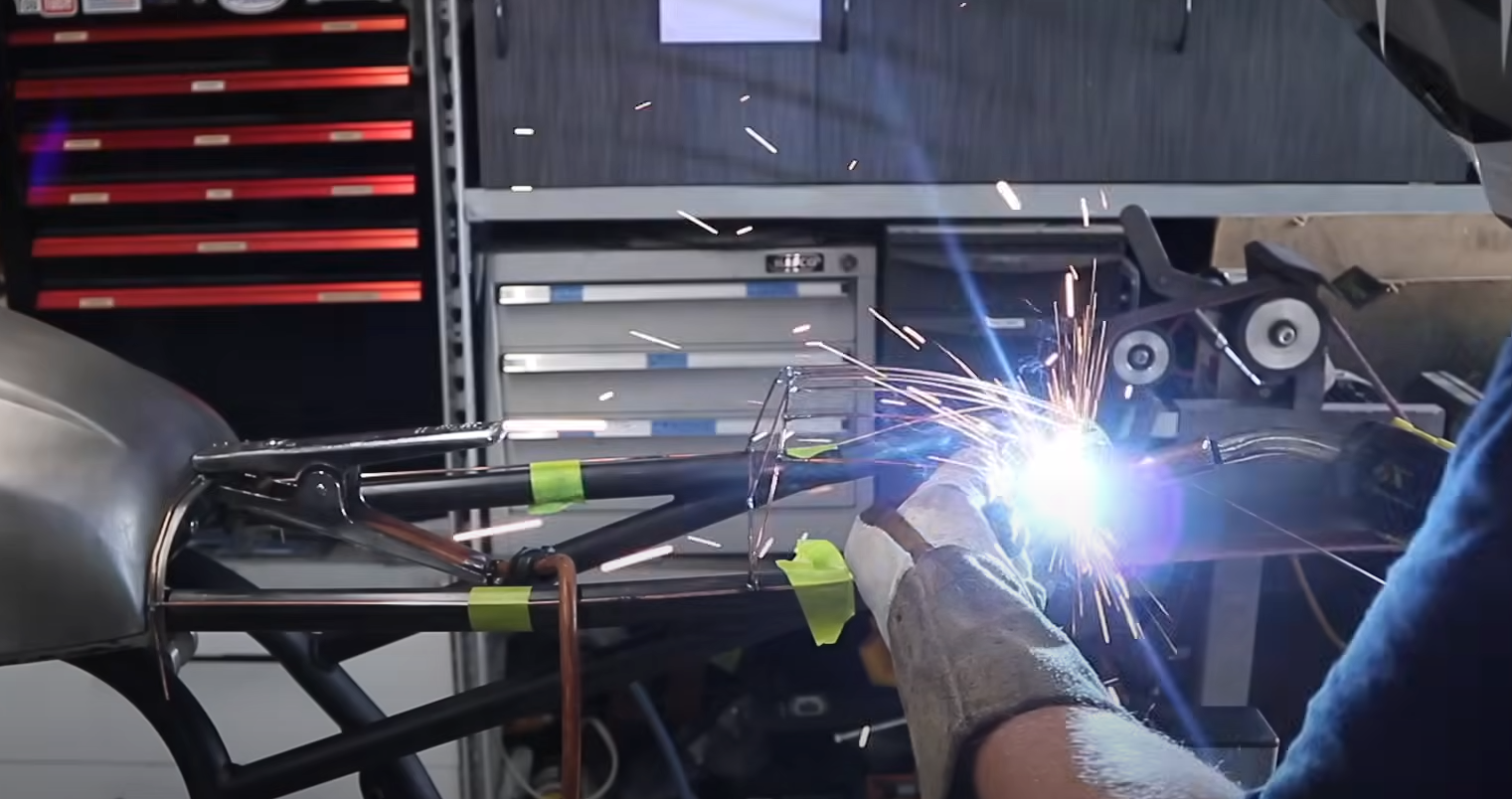

Becoming a member of the Hump to the Seat Base

With the entrance edge ready, he welded the hump instantly onto the seatpan. Cautious alignment made positive the 2 components sat flush towards one another. Small changes with instruments just like the shrinker-stretcher helped appropriate any distortion earlier than welding.

Clear Match and Skilled End

The ultimate meeting got here along with a exact match. The perimeters lined up easily, and the welds blended into the floor. The end result was a stable construction with a refined look, giving the venture a end that appeared factory-made. He even started shaping matching aspect panels to hold the identical stage of element throughout the construct.

Encouragement for Steel Shaping Fanatics

Benefits of Working with Steel

Steel shaping permits creators to show flat sheets into customized varieties with precision. It provides them management over symmetry, curves, and particulars that make every bit distinctive. The method can really feel rewarding as a result of it combines design, problem-solving, and hands-on ability.

Many discover the work gratifying as a result of it develops persistence and a spotlight to element. Even small changes, like shrinking or stretching metal, present progress in actual time. This makes the craft each sensible and motivating.

Starter Instruments Price Contemplating

Novices don’t want costly machines to start out shaping metallic. A number of easy instruments can go a great distance:

| Device | Function | Notes |

|---|---|---|

| Nylon hammer | Kinds and smooths metallic | Light on metal, helps management shaping |

| Sandbag | Helps hammering | Used for shrinking and stretching |

| Shrinking stump | Shapes curves | A picket block with a bowl lower into it |

| Dolly or vise setup | Hand planishing | Flattens and refines surfaces |

Non-obligatory instruments like a small English wheel or a hand planishing hammer can pace up ending work. Nonetheless, even with out them, cautious use of fundamental instruments can produce robust, correct outcomes.

By beginning easy and including instruments over time, fans can construct ability and confidence with out feeling overwhelmed.