QAD’s Tom Roberts explains how agentic AI is reworking automotive ERP, enabling planning, resilient provide chains, and quicker selections.

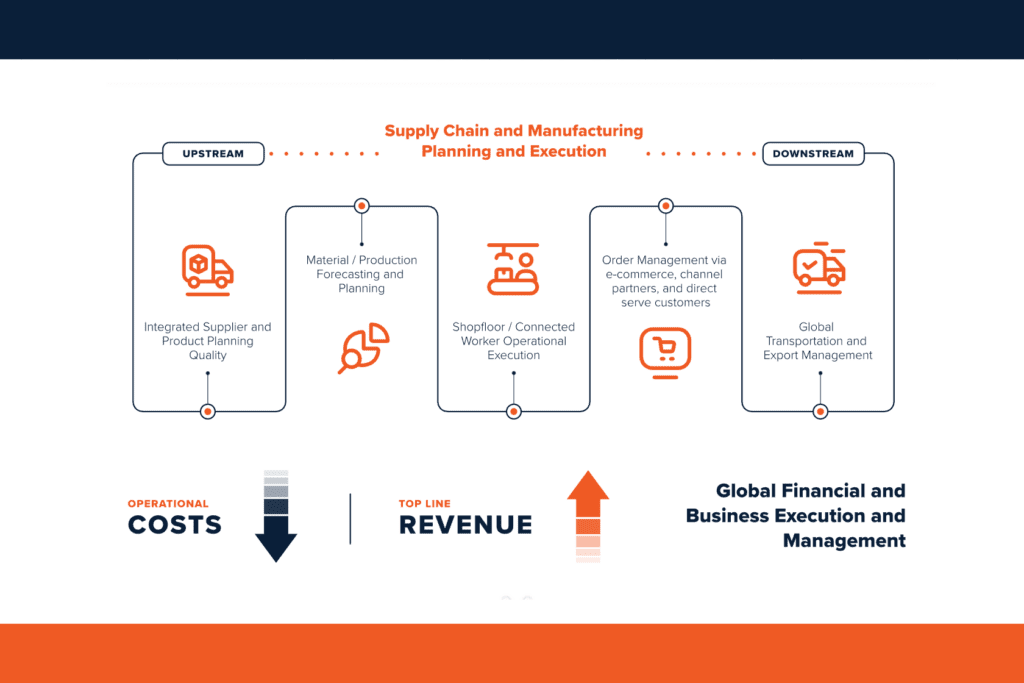

Automotive producers are navigating a interval of elementary change. Electrification, shifting rules, ongoing provide chain disruption, and the rising complexity of software-defined autos are difficult OEMs and suppliers to rethink how they plan, construct and ship at scale.

These forces are additionally prompting a more in-depth examination of the digital methods that underpin operations – significantly ERP, which performs a central position in coordinating manufacturing, supplies and international provide networks.

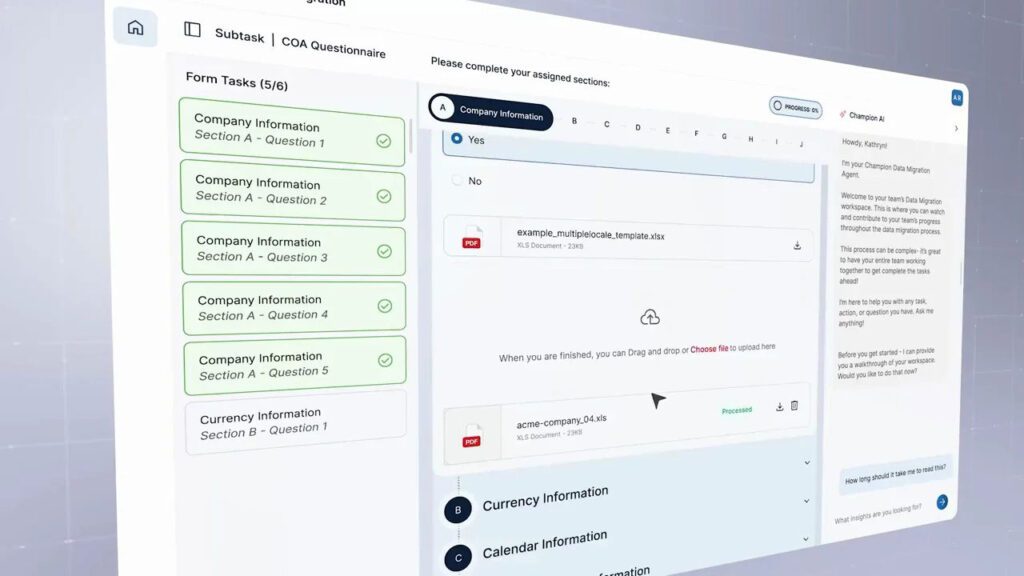

Towards this backdrop, QAD has launched the most recent evolution of its Adaptive ERP platform, now enhanced with Champion AI, its new agent-based synthetic intelligence framework. Designed to help extra responsive, action-oriented operations, the replace displays a broader business transfer towards methods that may automate routine selections and adapt rapidly to altering situations.

To discover the implications for manufacturing planning, stock administration, workforce enablement and wider manufacturing efficiency, Automotive World spoke with Tom Roberts, Vice President, Strategic Business Improvement at QAD.

How will Champion AI reshape automotive manufacturing because the business strikes towards electrification, software-defined autos, and extra complicated provide chains?

Probably the most seen challenges we’re seeing is demand volatility, significantly round electrified autos. Fluctuations in demand can considerably impression stock ranges and dealing capital if not managed proactively.

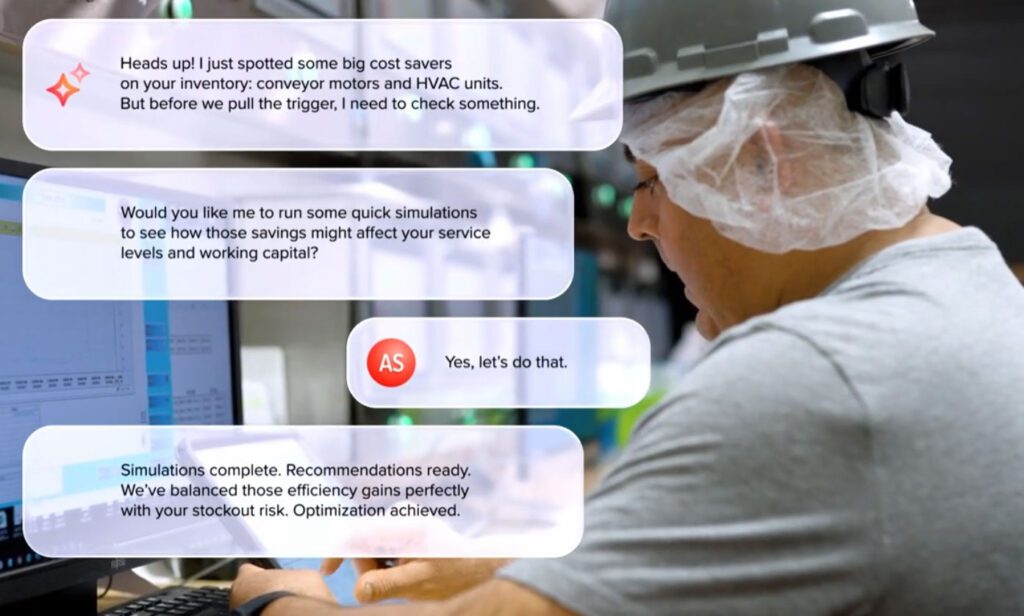

Champion AI consists of stock optimization capabilities that assist organizations modify extra dynamically as demand patterns change. On the sourcing facet, our optimization instruments present larger flexibility in post-purchase order administration, enabling consumers to guage and reply to date or amount adjustments and enhance visibility into exterior dangers.

For instance, we’ve begun incorporating geopolitical occasion mapping – initially centered on areas such because the Strait of Hormuz – so clients can visualize affected suppliers and logistics routes. This functionality is being expanded extra broadly as a part of our roadmap.

You describe QAD Adaptive with Champion AI as shifting ERP from a “system of report” to a “system of motion.” What does that appear like in apply for OEMs and suppliers?

ERP methods have traditionally been superb at recording transactions, however a lot of the follow-up work has remained handbook. I’ve been within the ERP house for the reason that late Nineteen Nineties, and plenty of of these core workflows haven’t basically modified.

With Champion AI, the system can detect when crucial data is lacking – corresponding to throughout an RFQ course of or post-purchase order administration – and provoke actions to resolve it, corresponding to contacting a provider to request the lacking knowledge.

This reduces the necessity for consumers to spend time chasing data, permitting them to deal with higher-value actions. That shift from passive record-keeping to energetic drawback decision is what we imply by a “system of motion.”

You’ve stated clients can see ROI inside weeks. What early good points ought to producers realistically count on?

One problem with ERP tasks is that success isn’t measured after go-live. Organizations typically transfer on with out formally assessing whether or not the system helps them meet their unique targets.

We deal with this via post-hypercare teaching, which helps clients measure efficiency towards KPIs and constantly refine processes utilizing Adaptive ERP and Champion AI capabilities. Whether or not the main focus is on stock and dealing capital, on-time-in-full supply, or procurement effectivity, the objective is to translate system adoption into measurable operational outcomes and sustained worth.

Stock volatility stays a significant problem within the automotive business. How does Champion AI differ from conventional MRP or forecasting instruments?

Quite than changing current planning instruments, Champion AI enhances them. In lots of organizations, stock parameters had been set years in the past and infrequently revisited as a result of reviewing them manually is time-consuming and sophisticated.

AI permits these parameters and efficiency indicators to be analyzed far more rapidly and persistently. What as soon as required intensive spreadsheet work and devoted assets can now be reviewed and optimized much more regularly, serving to producers reply to altering situations as an alternative of counting on static assumptions.

Automotive manufacturing scheduling is extremely complicated. What enhancements within the new launch assist crops handle variability and last-minute adjustments?

The secret’s visibility mixed with dynamic re-sequencing. Our answer gives a single supply of reality for orders, stock positions, and useful resource capability, so planners and scheduling engines are working from the identical, up-to-date data.

When disruptions happen – whether or not that’s a provider delay, gear situation, or materials variance – the system can consider alternate options corresponding to time beyond regulation or break up runs. It then proposes optimized re-sequences that reduce changeovers and defend crucial buyer deliveries, decreasing the necessity for expensive handbook firefighting on the store ground.

As connectivity throughout automotive crops will increase, how does an AWS-based structure help cybersecurity and compliance?

AWS gives a robust basis for Champion AI, together with data-at-rest encryption, knowledge isolation, and established safety guardrails. This enables clients to combine AI capabilities with their operational knowledge whereas sustaining safety and compliance necessities.

As AWS CEO Matt Garman has famous within the context of our partnership, the objective is to allow agent-based AI options that clients can deploy securely inside their very own environments.

How do QAD Redzone and Champion AI collectively help frontline operators on the store ground?

One instance is using AI-driven “Recreation Prepared” shift summaries. Incoming groups obtain a transparent view of key occasions throughout security, manufacturing, high quality, and reliability, together with prioritized motion suggestions earlier than a shift even begins.

When downtime happens, Champion AI can increase troubleshooting by analyzing the operational context, drawing on historic resolutions, real-time knowledge, and business requirements to counsel doubtless root causes and subsequent actions. It may additionally automate follow-up duties, corresponding to creating upkeep work orders.

As well as, operators obtain run predictions initially of every manufacturing run, together with estimated run instances and certain points, enabling groups to arrange proactively reasonably than reacting after issues come up.

Wanting forward, what extra agentic AI capabilities will automotive producers want because the business continues to evolve?

One main shift can be in how customers work together with enterprise methods. AI-driven interfaces are more likely to scale back reliance on conventional transaction screens. For instance, a person may create a purchase order requisition via a conversational interface, with the system guiding them to offer the required data and studying from prior conduct over time.

Past usability, producers are centered on decreasing waste and value. Superior causality detection may help establish the drivers of inefficiency and information corrective actions earlier than suboptimal selections are executed.

Lastly, provide chain resilience will stay crucial. Agentic AI embedded throughout demand administration, scheduling, forecasting, and different sourcing may help organizations reply extra successfully to disruption and uncertainty as platforms, rules, and ecosystems proceed to vary.

Click on right here to discover QAD’s Adaptive ERP platform.

Sponsored Content material: This text was produced on behalf of QAD. Whereas QAD supplied data and professional commentary, Automotive World retained accountability for the ultimate content material.