The Yamaha RD 350 earned a status for being each thrilling and harmful, recognized for its gentle body and highly effective engine. Years later, a builder in Brazil got down to reimagine this traditional motorbike, mixing its legacy with fashionable engineering. His purpose was to create one thing that appeared and felt like a brand new model of the RD 350, whereas bettering security, reliability, and efficiency.

The venture started with restricted unique elements and a transparent imaginative and prescient. Utilizing a contemporary Yamaha R3 engine, strengthened body, and superior 3D printing, the builder remodeled the idea right into a practical and trendy machine. Each element—from the brakes to the fairing—was rigorously designed to mirror each innovation and respect for the unique mannequin.

Key Takeaways

- The venture reimagines a traditional motorbike with fashionable engineering.

- Superior instruments like 3D printing helped obtain exact {custom} elements.

- The construct balances efficiency, security, and design in a contemporary interpretation.

Historical past and Legacy of the Yamaha RD 350

Early Growth and Evolution

The Yamaha RD 350 earned a status as some of the highly effective and unpredictable bikes of its time. Riders usually known as it the “Black Widow” or “Widow Maker” due to its intense efficiency and weak braking system. Its gentle body and robust two-stroke engine created an exhilarating however dangerous driving expertise.

In Brazil, the primary RD 350 fashions featured a half fairing, a design alternative that impressed later {custom} initiatives. Builder Renato Frateschi, from Frateschi Storage, honored that heritage when he created a contemporary model utilizing the identical fairing type. His venture started in 2022, primarily based on a shopper’s request for a novel construct.

| Key Options | Unique RD 350 | Customized Mission |

|---|---|---|

| Engine Sort | 2-Stroke | 4-Stroke (Yamaha R3) |

| Fairing | Half | Semi |

| Brakes | Fundamental | Brembo, 300 mm discs |

| Body | Mild, versatile | Bolstered for stability |

Renato changed the uncommon unique engine with a Yamaha R3 motor to remain inside finances. To boost efficiency, he added a turbo system, which required in depth body modifications. He strengthened the chassis, improved suspension, and fitted 17-inch wheels for higher dealing with.

Affect on Motorbike Design and Lovers

The RD 350’s legacy continues via {custom} builds like Renato’s. His use of 3D printing and augmented actuality instruments confirmed how fashionable expertise can revive traditional designs. He created the rear and entrance fairings utilizing large-format 3D printers, a troublesome activity on the time because of materials limits and warmth resistance challenges.

This venture balanced fashionable reliability with traditional type, protecting the aggressive look of the unique whereas bettering trip high quality. The construct featured a Triumph Daytona 675 swingarm, {custom} aluminum elements, and exact engineering work.

Though the four-stroke turbo engine lacks the uncooked energy of the unique two-stroke, the venture captured the spirit and perspective of the RD 350. It demonstrated how the motorbike’s affect nonetheless conjures up builders to mix custom with innovation.

The Customized Mission Imaginative and prescient

Renato Frateschi and His Workshop

Renato Frateschi, proprietor of Frateschi Storage in Brazil, led this practice Yamaha venture with precision and persistence. The work started in 2022 when a shopper requested for a motorbike that felt distinctive and fashionable. Renato urged utilizing a Yamaha RD as the bottom, though solely the gas tank, body, and wheels have been accessible.

To remain inside finances, he changed the uncommon RD engine with one from a Yamaha R3. This new engine was heavier and fewer highly effective, so he determined to add a turbo to spice up efficiency. Adapting the R3 engine required body modifications to deal with the additional dimension and weight. Renato additionally strengthened the chassis to enhance stability and security.

He put in Brembo entrance brakes with 300 mm discs and used a Triumph Daytona 675 swingarm for higher dealing with. The 17-inch wheels added agility and a wider stance. Many of those elements needed to be custom-designed, 3D printed, and machined from aerospace aluminum, exhibiting the excessive stage of technical talent behind the venture.

| Key Upgrades | Supply/Technique |

|---|---|

| Engine | Yamaha R3 (4-stroke) |

| Swingarm | Triumph Daytona 675 |

| Brakes | Brembo, 300 mm discs |

| Body | Bolstered and modified |

| Elements | 3D printed and CNC machined |

What Sparked the Construct

The design took form via 3D modeling, scanning, and augmented actuality, permitting exact changes earlier than fabrication. Renato printed each the rear part and semi-fairing utilizing superior 3D printers, which was unusual on the time in Brazil.

The semi-fairing design mirrored the first RD 350 produced in Brazil, which additionally featured a half fairing. This connection made the styling alternative each sensible and traditionally constant. The ultimate outcome appeared like a fashionable RD 350, full with twin headlights and a compact rear gentle with built-in flip alerts.

Renato aimed to seize the spirit of the unique RD whereas utilizing fashionable expertise and supplies. Regardless that the trip couldn’t absolutely match the uncooked really feel of a two-stroke engine, the venture achieved a robust steadiness between traditional character and fashionable efficiency.

Engine Choice and Modifications

Deciding on the Yamaha R3 Energy Unit

Renato Frateschi started the venture with just a few parts: the body, wheels, and gas tank. Discovering an unique RD 350 engine proved troublesome and costly, so he selected the Yamaha R3 engine as a substitute. The R3’s 4-stroke design provided reliability and fashionable efficiency, though it was heavier and fewer highly effective than the RD’s 2-stroke motor. This alternative allowed the venture to remain inside finances whereas offering a stable base for additional upgrades.

| Specification | RD 350 (Unique) | R3 (Chosen Engine) |

|---|---|---|

| Sort | 2-stroke | 4-stroke |

| Weight | Lighter | Heavier |

| Energy | Larger | Decrease |

| Availability | Uncommon | Widespread |

| Value | Excessive | Reasonable |

Turbo System Implementation

To boost efficiency, Renato added a turbocharger to the R3 engine. This required the creation of a number of {custom} elements, all designed and produced in-house. Utilizing 3D printing and CAD modeling, he developed the fittings and mounts wanted to combine the turbo system securely. The outcome was a cleaner and extra environment friendly set up that balanced energy beneficial properties with reliability.

Key fabrication instruments:

- 3D printers for {custom} parts

- CAD software program for design precision

- Machined aluminum for energy and sturdiness

Difficulties in Engine Set up

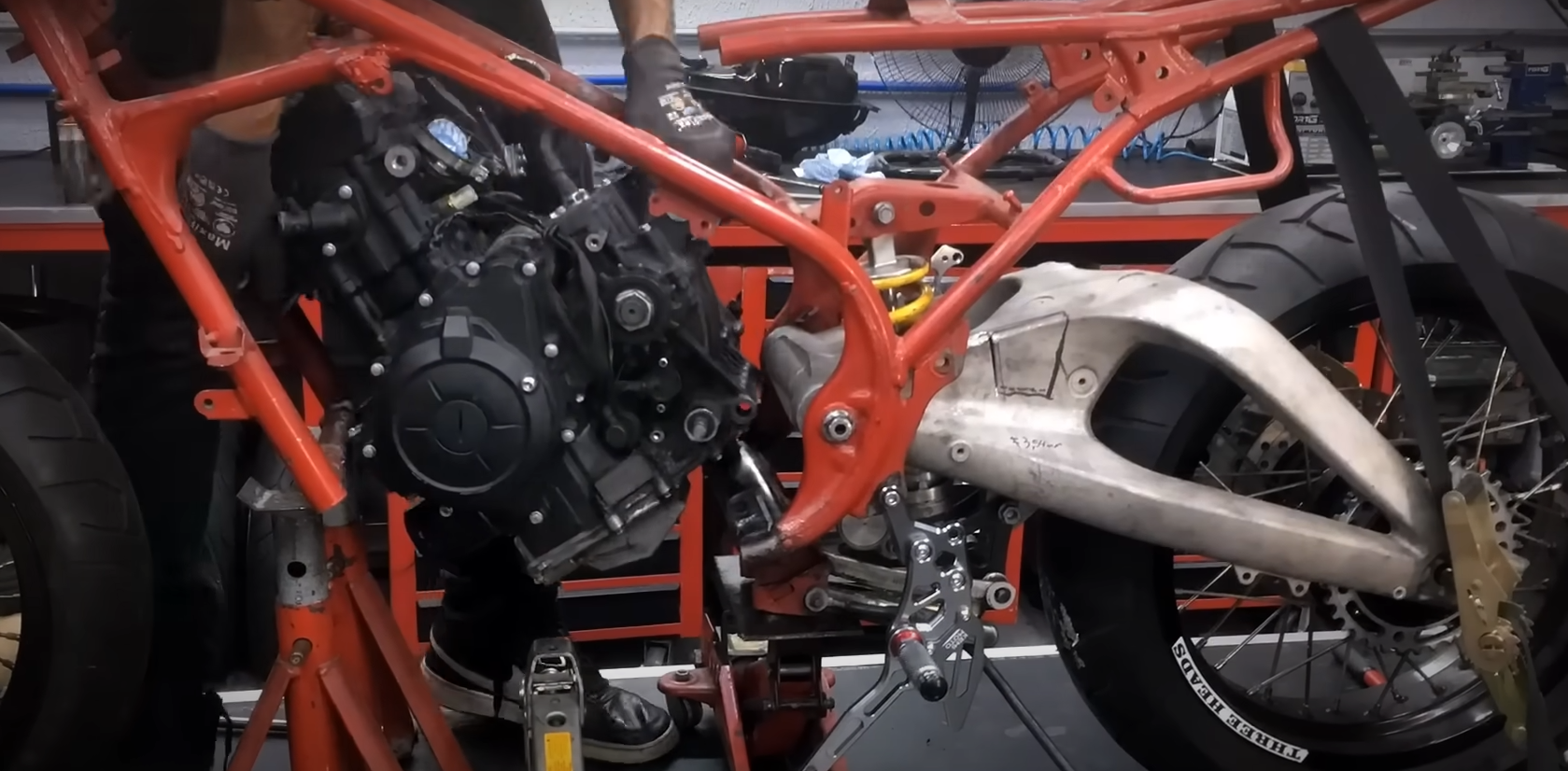

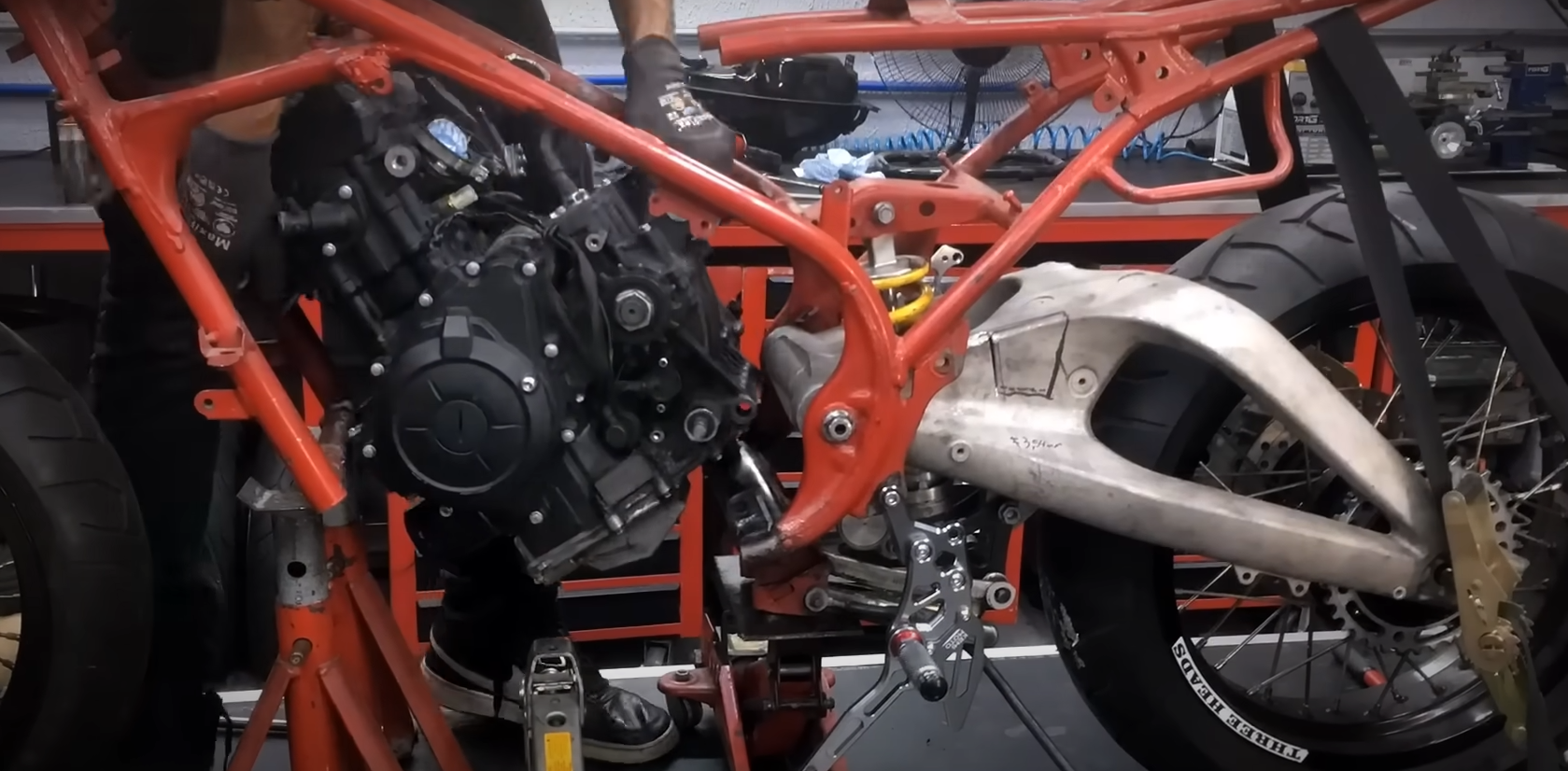

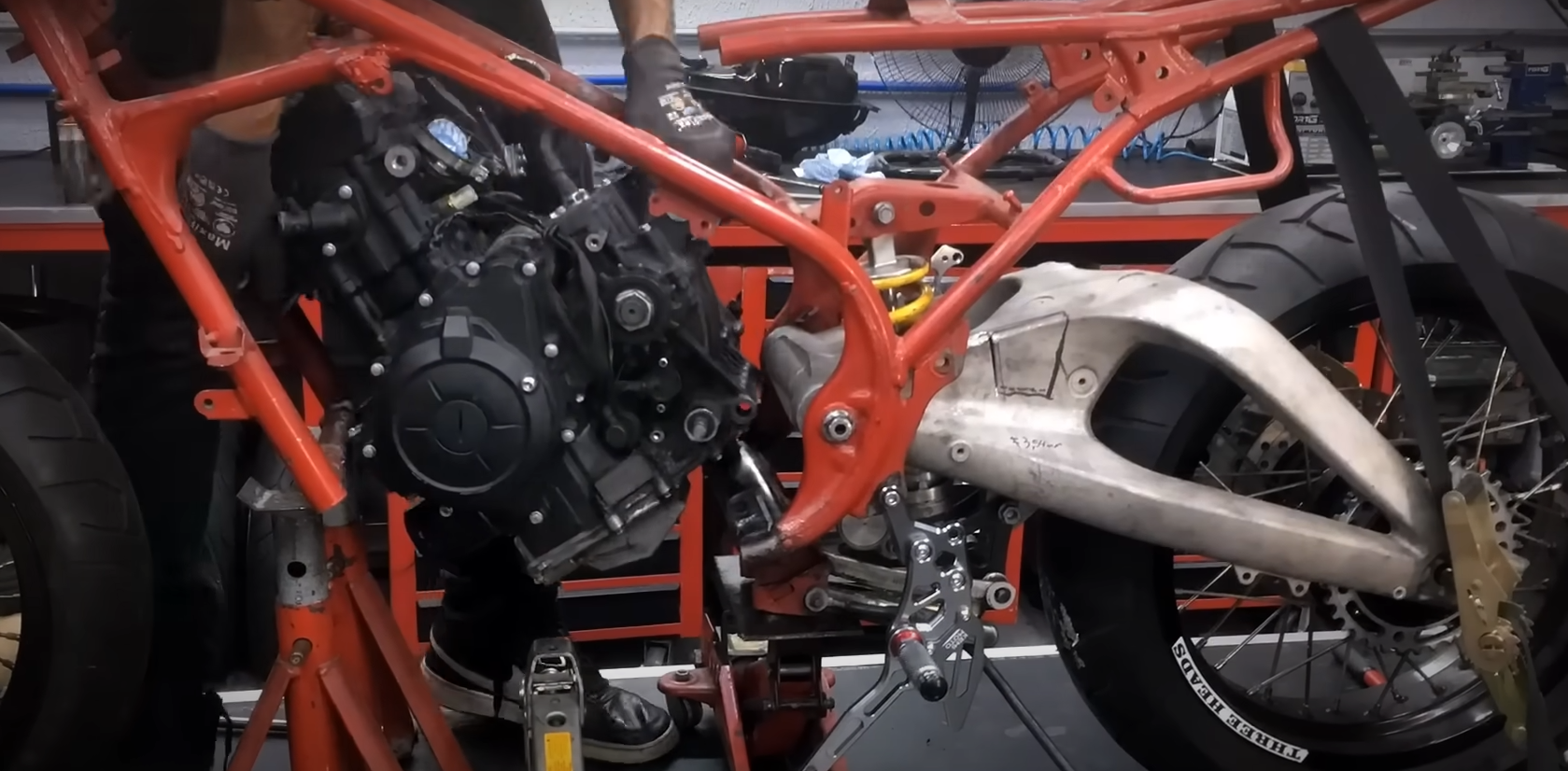

Becoming the R3 engine into the RD 350 body was removed from easy. The brand new engine’s bigger dimension and added weight demanded modifications to the body. Renato strengthened the construction to enhance rigidity and security whereas preserving the unique traces.

He additionally upgraded a number of elements to deal with the elevated efficiency:

- Brembo entrance brakes with 300 mm discs

- Triumph Daytona 675 swingarm for higher stability

- 17-inch wheels for improved agility

These changes ensured the motorbike maintained correct steadiness and dealing with regardless of the engine swap and turbo addition.

Chassis and Body Enhancements

Body Strengthening and Construction Enhancements

Renato redesigned the unique body to deal with the additional weight and dimension of the R3 engine. The inventory RD 350 body was recognized for twisting beneath stress, so he strengthened it with out altering its general form.

He added structural helps to enhance rigidity and guarantee secure dealing with. This improve allowed the bike to deal with fashionable parts similar to bigger wheels and stronger brakes. The ultimate construction stored the traditional traces of the RD whereas bettering security and efficiency.

| Element | Modification | Objective |

|---|---|---|

| Body | Bolstered joints and tubing | Scale back flex and enhance stability |

| Engine Mounts | Customized-fitted | Help heavier 4-stroke engine |

| Geometry | Maintained unique proportions | Protect traditional RD look |

Suspension and Experience Management Upgrades

To match the stronger body, Renato upgraded the suspension and dealing with system. A Triumph Daytona 675 swingarm changed the previous one, giving the motorbike a extra balanced stance and higher traction. Adapting it required exact alignment with the Yamaha body, however the effort paid off.

The 17-inch wheels improved cornering and agility in comparison with the unique setup. Brembo entrance brakes with 300 mm discs supplied dependable stopping energy. A {custom} caliper mount, designed with CAD software program and machined from aerospace aluminum, ensured good match and performance.

Key upgrades included:

- Wider wheels for improved grip

- Fashionable swingarm for higher stability

- Excessive-performance brakes for stronger management

Brake and Wheel Upgrades

Brembo Entrance Brake Setup

Renato geared up the motorbike with Brembo entrance brakes that use 300 mm discs for stronger stopping energy. He designed and produced the caliper mounts himself utilizing CAD modeling, 3D printing, and aerospace-grade aluminum machining.

| Element | Course of | Materials |

|---|---|---|

| Caliper Provider | CAD Designed & 3D Printed | Aerospace Aluminum |

| Brake Discs | 300 mm | Metal |

| Entrance Calipers | Brembo | — |

These upgrades improved braking precision and reliability whereas protecting the {custom} design in step with the remainder of the construct.

Wider Wheel Setup and Swingarm Modification

The motorbike now runs on 17-inch wheels, changing the narrower originals. The broader wheels enhanced stability and cornering, giving the bike faster dealing with.

Renato tailored a Triumph Daytona 675 swingarm to suit the Yamaha body. The adjustment required cautious alignment, however the general size of the motorbike stayed almost the identical.

Key enhancements:

- Wider wheels for higher grip

- Stronger swingarm from a contemporary sportbike

- Maintained unique body proportions

These adjustments balanced the additional weight of the brand new engine and boosted the bike’s agility and management.

Modern Use of 3D Printing

Creation and Constructing Course of

Renato Frateschi used 3D printing to form a number of {custom} elements for his Yamaha venture. He designed the rear part and fairing utilizing digital fashions, scanners, and augmented actuality instruments to visualise the ultimate type earlier than printing.

He printed each small and enormous parts, testing completely different supplies and shapes till he reached the specified energy and end. The rear gentle and built-in flip alerts have been additionally a part of this printed design, giving the motorbike a clear and fashionable look.

| Element | Fabrication Technique | Materials | Objective |

|---|---|---|---|

| Caliper Provider | 3D printed + machined | Aerospace aluminum | Mount Brembo brakes |

| Rear Part | 3D printed | Composite filament | Light-weight bodywork |

| Fairing | 3D printed | Bolstered polymer | Aerodynamic styling |

Fixing Design and Engineering Points

Printing massive elements that might deal with stress, torsion, and warmth was a serious problem. Two years earlier, few printers in his area might handle this stage of complexity. Renato experimented with completely different printer settings and supplies till the elements met his requirements for sturdiness.

He additionally confronted alignment points when adapting elements just like the Triumph swingarm and Yamaha body. Through the use of CAD modeling and exact 3D prints, he created correct fittings and mounts. These instruments helped him refine the geometry and make sure the motorbike stored its balanced proportions.

By means of this course of, he improved his technical expertise and set a basis for future {custom} builds that mix conventional mechanics with superior digital fabrication.

Fashionable Styling and Ending Touches

Design Selections

Renato Frateschi gave the motorbike a daring and fashionable look whereas protecting the traces of the traditional RD 350. He changed the unique bodywork with elements made utilizing 3D printing, together with the rear part and semi-fairing. This methodology allowed him to check shapes and fitment with precision earlier than closing meeting.

He used 3D scanners, modeling software program, and augmented actuality to visualise how every half would seem on the completed bike. These instruments helped him refine the design till it matched the shopper’s expectations. The result’s a motorbike that appears factory-built however with a sharper, extra aggressive stance.

| Function | Method Used | Consequence |

|---|---|---|

| Physique panels | 3D printed | Light-weight and {custom} match |

| Body traces | Bolstered and retained | Stronger but traditional form |

| Paint scheme | Fashionable interpretation | Displays the RD heritage |

Lighting and Fairing Design

The entrance fairing retains a semi-covered type that connects to the primary RD 350 fashions produced in Brazil. This alternative provides the motorbike a way of continuity whereas including a contemporary contact. Two compact headlights sit in entrance, making a clear and assertive look.

On the rear, a minimalist taillight combines brake and switch sign features in a single piece, protecting the design easy and neat. The fairing and lighting format steadiness old-school inspiration with up-to-date supplies and expertise, giving the bike a definite fashionable id.

Efficiency and Using Expertise

Comparability with the Basic RD 350

The unique RD 350 earned its fierce status for being gentle, quick, and troublesome to deal with. This new model retains the spirit however makes use of a Yamaha R3 four-stroke engine as a substitute of the unique two-stroke. The change made the bike heavier but additionally extra dependable and simpler to keep up.

To get better some misplaced energy, the builder added a turbocharger, giving the R3 engine a stronger response. The body was strengthened to deal with the additional weight and energy, protecting the identical normal form however bettering stability. The 17-inch wheels and Brembo entrance brakes with 300 mm discs add management and stopping energy that the previous RD by no means had.

| Function | Basic RD 350 | Customized Construct |

|---|---|---|

| Engine Sort | 2-stroke | 4-stroke (R3) with turbo |

| Body | Unique, versatile | Bolstered for rigidity |

| Wheels | Slim | 17-inch, wider |

| Brakes | Fundamental | Brembo, 300 mm discs |

Dealing with and Experience Really feel

The modified body and suspension give the motorbike a extra balanced and safe trip. The Triumph Daytona swingarm provides precision when cornering, whereas the broader tires enhance traction.

Regardless that the turbocharged R3 engine can’t absolutely match the sharp response of the previous two-stroke, it nonetheless delivers an partaking and easy energy curve. The improved geometry and stronger parts make it simpler to regulate, particularly at increased speeds.

The result’s a motorbike that blends fashionable reliability with the traditional vitality that made the RD 350 so memorable.

Mission Outcomes and Subsequent Steps

Key Takeaways

Renato Frateschi’s {custom} Yamaha venture confirmed how artistic design and sensible engineering can work collectively. He changed the unique RD 350 engine with a Yamaha R3 motor to fulfill price and availability limits, then added a turbo to spice up efficiency.

He strengthened the body to scale back torsion and enhance dealing with. The usage of 3D printing, CAD design, and augmented actuality allowed him to construct and take a look at distinctive elements just like the fairing, tail part, and brake parts. These strategies saved time and improved accuracy.

Renato found that adapting a contemporary engine to a classic body required fixed adjustment. The method taught him how one can steadiness weight, construction, and energy whereas sustaining the unique character of the bike.

| Element | Modification | Objective |

|---|---|---|

| Body | Bolstered and reshaped | Enhance stability |

| Engine | Yamaha R3 with turbo | Enhance energy |

| Swingarm | From Triumph Daytona 675 | Improve suspension |

| Brakes | Brembo with 300 mm discs | Enhance stopping energy |

| Bodywork | 3D printed | Scale back weight and permit {custom} design |

Future Builds

Renato plans to use what he realized to imminent bikes. He goals to refine 3D printing for structural elements, enhance engine integration, and additional take a look at augmented actuality modeling for shopper previews.

His subsequent construct will probably proceed mixing fashionable expertise with traditional design. The main target will keep on exact engineering, sturdy efficiency, and a clear factory-style end that respects the legacy of the unique RD 350.