Sponsored by H.B. Fuller.

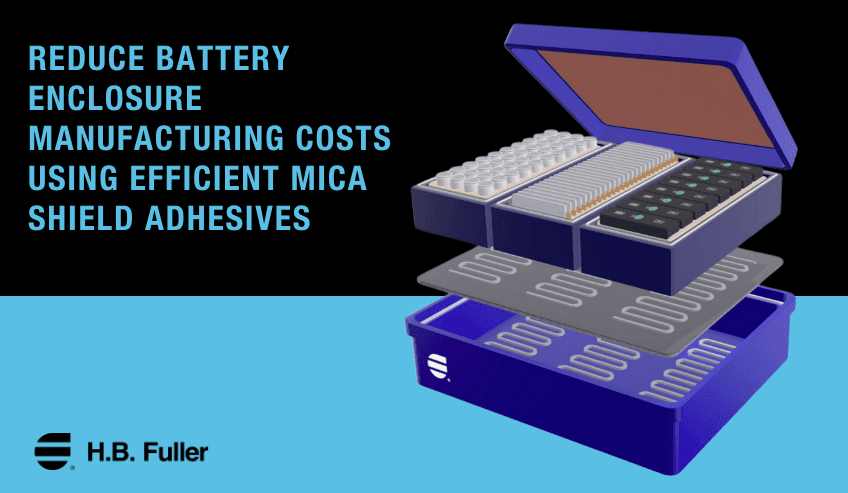

Because the EV business developments towards mass adoption, battery security and manufacturing effectivity have turn into crucial focal factors for OEMs and battery designers. Among the many most urgent issues are thermal dissipation, electrical isolation, and the prevention of thermal runaway and propagation—points that may compromise each efficiency and security. To handle these challenges, producers are more and more turning to superior supplies and adhesive applied sciences that not solely improve security but in addition streamline manufacturing and scale back prices.

Security-Pushed Innovation in Battery Design

Battery packs are advanced programs that should stand up to excessive temperatures, mechanical stress, and potential fireplace hazards. Security methods typically embrace the combination of thermal administration programs and thermal obstacles designed to comprise or mitigate the results of fireplace. One such barrier materials is mica, valued for its wonderful thermal and electrical insulation properties. Nonetheless, incorporating mica into battery enclosures presents its personal set of producing challenges, significantly round adhesion and course of effectivity.

Conventional bonding strategies—akin to double-sided tapes, two-component polyurethanes (2K PU) andnon-reactive sizzling soften pressure-sensitive adhesives (PSAs)have limitations by way of cycle time, reliability, and adaptableness to advanced geometries. These limitations can result in elevated scrap charges, longer manufacturing cycles, and better general prices.

Optimizing Adhesive Efficiency in Battery Enclosures

H.B. Fuller, a world chief in adhesives and superior supplies, has developed a breakthrough answer to those challenges: EV Bond 775, a reactive sizzling soften adhesive engineered particularly for battery functions. This revolutionary materials is remodeling how mica shields are built-in into battery enclosures, providing vital benefits in efficiency, reliability, and value effectivity.

EV Bond 775 is designed to fulfill the rigorous calls for of battery manufacturing. It options:

- Lengthy open time of 10-Quarter-hour, permitting for versatile and exact meeting.

- Quick era of inexperienced energy, enabling speedy dealing with and lowering wait instances.

- Wonderful coat weight management, making certain constant software throughout advanced geometries.

- Compatibility with automated spray tools, supporting scalable, high-throughput manufacturing.

- Resistance to temperature fluctuations and vibration, crucial for long-term sturdiness inside battery packs.

Importantly, EV Bond 775 adheres successfully to a variety of substrates, together with mica, e-coated metal, aluminum, and composite supplies—making it a flexible answer for numerous battery designs.

Dramatic Reductions in Cycle Time and Scrap

When benchmarked in opposition to standard adhesives, EV Bond 775 delivers compelling efficiency enhancements:

- In comparison with 2K polyurethane, which usually requires a 20-minute cycle time, EV Bond 775 reduces this to only 20 seconds—a 60-fold enchancment that interprets immediately into sooner throughput and decrease labor prices.

- In comparison with PSA tape, EV Bond 775 reduces failure charges upwards of 10%%, minimizes downtime, and allows in-house integration. Its skill to adapt to advanced geometries with precision and consistency eliminates the necessity for extra manufacturing steps, additional lowering prices.

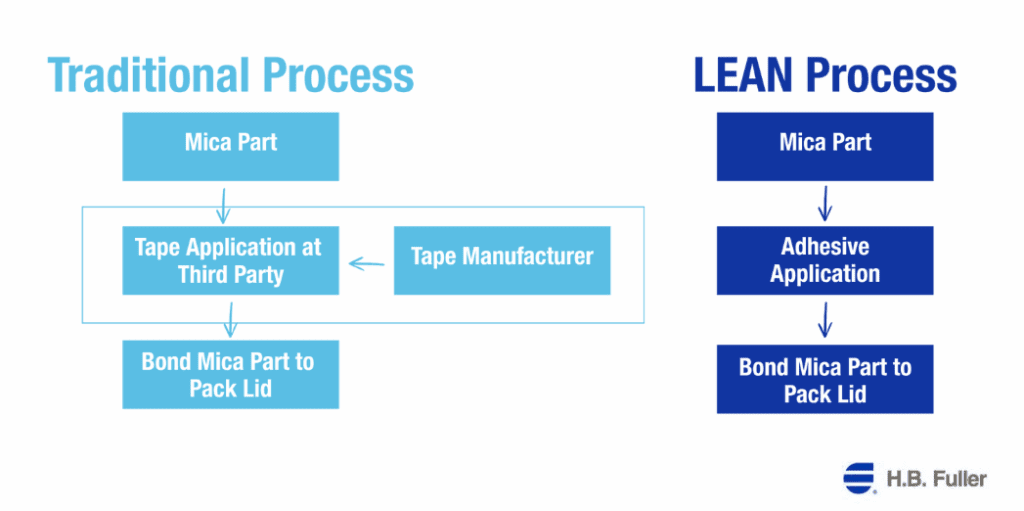

This effectivity is clearly illustrated within the comparability between conventional and lean manufacturing processes for mica protect integration (Determine 1). Within the Conventional Course of, mica elements are despatched to a third-party for tape software, introducing delays, added logistics, and dependency on exterior suppliers.

The LEAN Course of, enabled by EV Bond 775, eliminates these steps by permitting direct adhesive software in-house. This not solely streamlines operations but in addition reduces lead instances and value of possession.

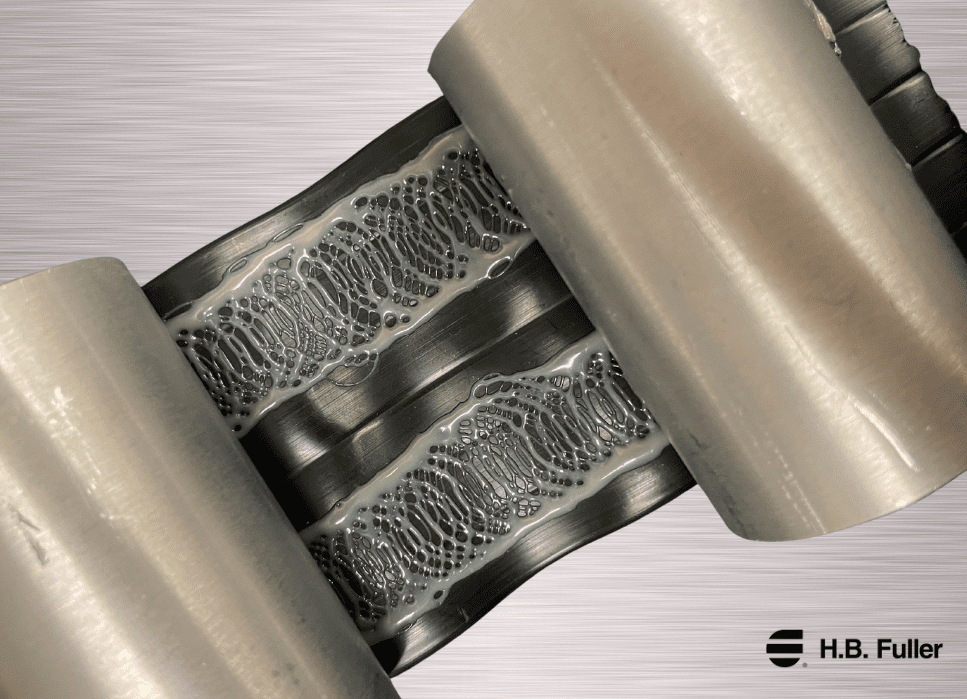

The adhesive’s quick and simple software course of permits for in-situ bonding, which means mica panels will be utilized immediately throughout meeting with out pre-treatment or curing delays. As soon as utilized, EV Bond 775 instantly holds giant mica panels in tensile mode, supporting a versatile and environment friendly manufacturing course of.

Past Mica Shields: Increasing Purposes in Battery Programs

Whereas EV Bond 775 is optimized for bonding mica shields in battery enclosures, its utility extends to different crucial parts. For instance, it may be used to connect cells to cooling snakes, a key factor in sustaining temperatures in battery programs. This versatility makes EV Bond 775 a beneficial instrument throughout the battery worth chain, supporting safer, extra dependable, and extra environment friendly vitality storage options.

A Smarter Option to Construct Safer Batteries—with H.B. Fuller

H.B. Fuller is greater than a supplies provider—it’s a strategic companion to battery producers and OEMs navigating the evolving panorama of electrical mobility and clear vitality. With a rising portfolio of high-performance adhesives and encapsulants, H.B. Fuller helps prospects meet the calls for of next-generation battery programs. From thermal administration and structural bonding to battery sealing and encapsulation, H.B. Fuller’s options are engineered to reinforce security, reliability, and sustainability.

Because the EV market continues to develop, producers face growing stress to optimize efficiency whereas controlling prices. EV Bond 775 exemplifies how H.B. Fuller is rising to this problem—delivering supplies that not solely meet technical necessities but in addition unlock new efficiencies in manufacturing.

Attain out to H.B. Fuller as we speak to find out how EV Bond 775 can remodel your battery manufacturing course of.