Constructing a customized Honda CX-500 on a finances takes cautious planning and hands-on creativity. The method up to now has included reshaping the body, crafting a seat base, creating aspect covers, and growing a novel headlight bracket. Every step makes use of inexpensive supplies and easy instruments to maintain prices low whereas guaranteeing that each modification suits the bike’s look and construction.

For the subsequent stage, consideration turns to creating and mounting customized gauge holders and a rear mud guard. The method sticks with do-it-yourself options by shaping metal for the brand new fender, determining sturdy mounting factors, and utilizing intelligent methods like wedges and riv nuts for safe set up. Particulars like a tail tidy and customized flip sign mounts end off the again finish, exhibiting how basic components will be modified or changed to suit new wants with out spending an excessive amount of.

Key Takeaways

- The construct focuses on budget-friendly, hands-on modifications.

- Customized options are used for the gauges, fender, and mounting.

- DIY methods assist hold the undertaking inexpensive and sensible.

Value-Efficient CX-500 Construct Abstract

Modifying the Body and Including a Seat Loop

The body was trimmed again and a brand new rear loop was added. The loop included a slot for an built-in tail mild. These steps made house for customized upgrades whereas retaining prices down.

Making a Customized Seat Platform and Tail Gentle

A seat base was formed from heated thermoplastic, fitted carefully to the subframe, and mounted with seat clips. Foam was trimmed and formed for consolation. The tail mild was constructed into the again body loop for a blended look.

Fabricating Distinctive Facet Panels

Facet panels had been made out of scratch and thoroughly formed to match the CX-500’s fashion. The method took time however allowed for an ideal match. Creating them in-house made the construct extra inexpensive and private.

Designing a Headlight Mount

A customized bracket was made for the headlight utilizing fundamental instruments and provides. This method allowed them to save cash and alter the match as wanted. The mount holds the headlight firmly and suits with the remainder of the modifications.

Making Your Personal Gauge Cups

Creating Aluminium Gauge Holders

To make customized gauge holders, begin by reducing and shaping aluminium tubes and discs. These components must be welded collectively to type a cup. After welding, they need to be machined to easy out tough areas and create a clear curve.

Tip: The nearer you machine to the weld, the thinner the steel will get. Keep away from making it too skinny on the base.

Chopping, Shaping, and Ending

The cups are refined utilizing a lathe to get the specified curve. Generally, if the weld will get too skinny, the cup might come aside and must be re-welded. A number of rounds of welding and machining could also be wanted for the very best outcomes.

Tables, grinders, and sanders assist easy out sharp edges. Lathes are used to get an excellent end all the way in which round.

Ring Edges and Methods to Connect

A bezel will be made to suit across the prime of the cup. This hides tough welds and offers a cleaner look. Mounting decisions matter too. Tabs or easy brackets will be welded or bolted for simple attachment to the bike.

In case you are drilling holes to mount the cups, use rubber grommets to guard wires and keep away from harm.

Different Gauge Concepts

As an alternative of fabricating from steel, 3D printing is an possibility for making these cups. This methodology can save effort and time. You can additionally modify current plastic components to suit your gauges, becoming them by reducing them to measurement and heating to form.

Each steel and plastic gauge holders will be hooked up with riv nuts if you do not need to weld. Riv nuts provide you with a threaded insert for simple screwing and unscrewing.

| Methodology | Instruments | Expertise Wanted |

|---|---|---|

| Aluminium Fabrication | Welder, Lathe | Metalwork |

| 3D Printing | 3D Printer, File | Fundamental CAD |

| Modified Plastic | Noticed, Warmth gun | Gentle Chopping |

Select the strategy that matches your instruments and abilities for the very best outcome.

Constructing a Customized Rear Mudguard

Selecting and Shaping Metal for the Fender

The builder begins with a sheet of cold-rolled delicate metal, 1.2 mm thick. This thickness is robust sufficient for fender use however nonetheless bends with frequent instruments. The metal is reduce and formed by hand to match the look wanted for the bike.

Key Supplies:

- Chilly-rolled delicate metal

- Authentic plastic guard (used as a information and internal liner)

The piece is shaped with a nylon hammer to get an preliminary curve, then checked for match on the body.

Making Curves and Smoothing Out the Form

To shrink and curve the metal, a energy hammer is used. This makes sections of the fender tuck in the place wanted. After shrinking, a planishing hammer smooths any tough areas and helps even out the curves.

Instruments for the Job:

| Device | What It Does |

|---|---|

| Energy Hammer | Shrinks and curves metal |

| Planishing Hammer | Flattens and smooths |

| English Wheel | Refines the curves |

The method is repeated till the fender matches the specified form.

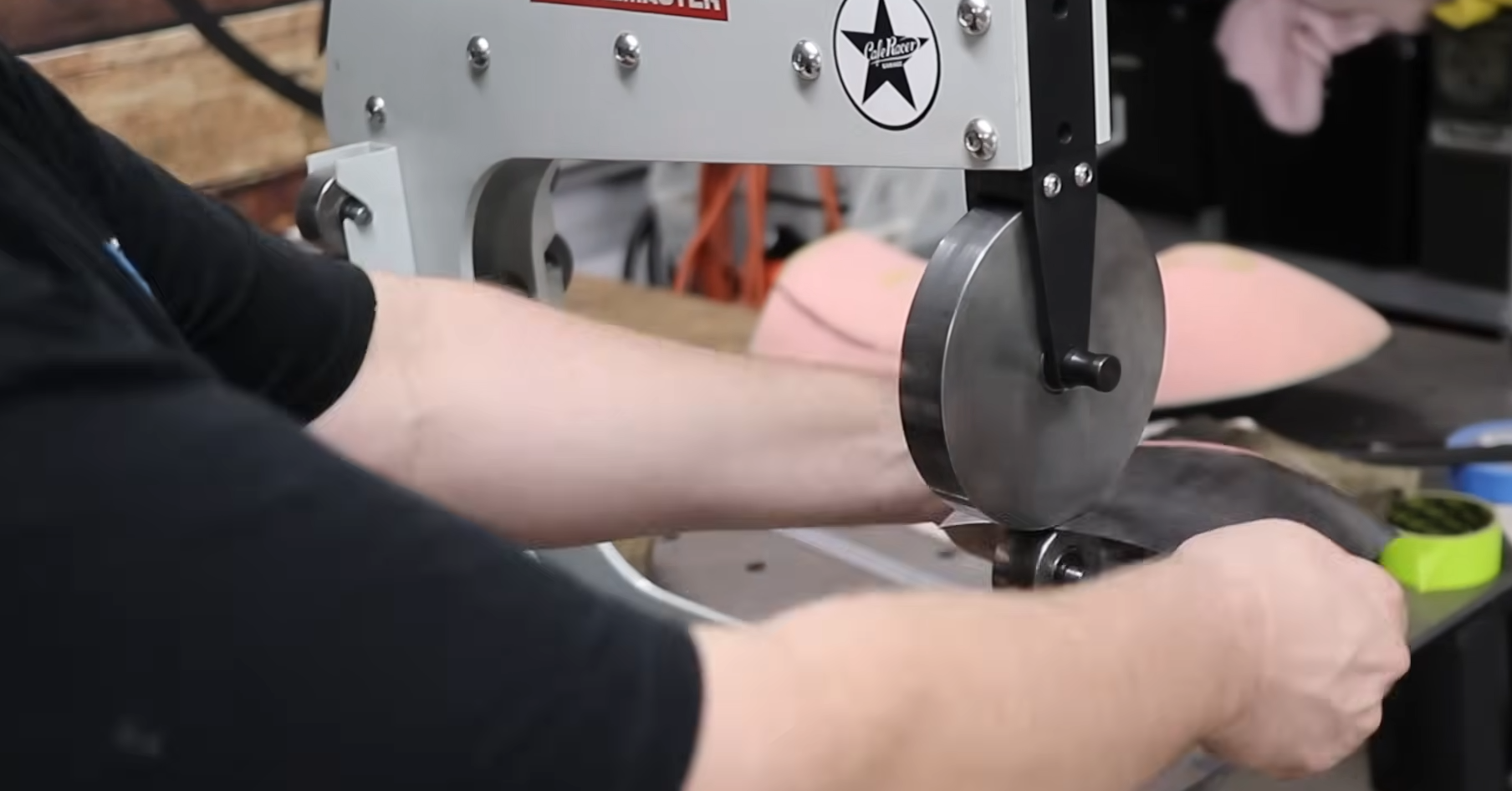

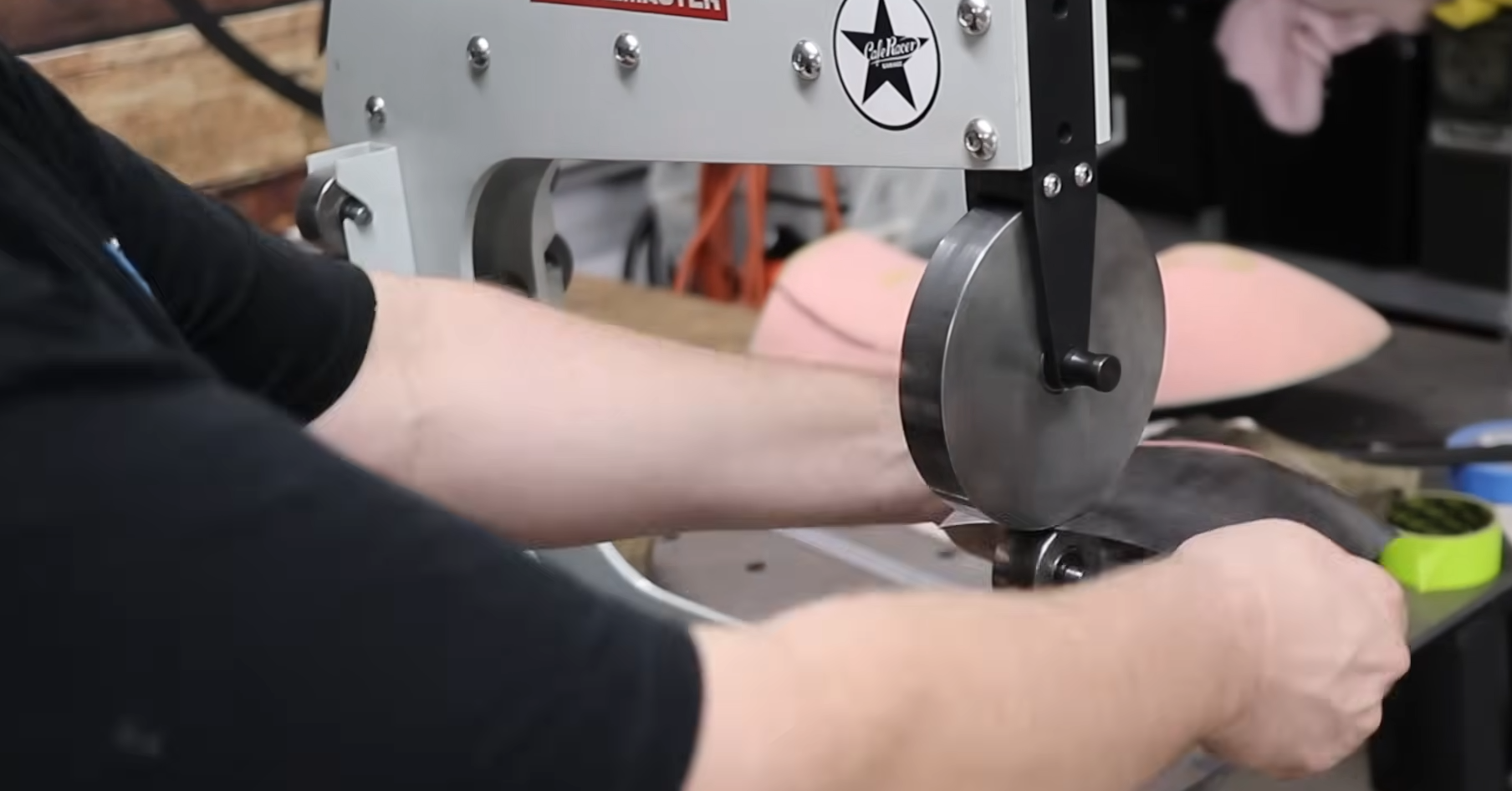

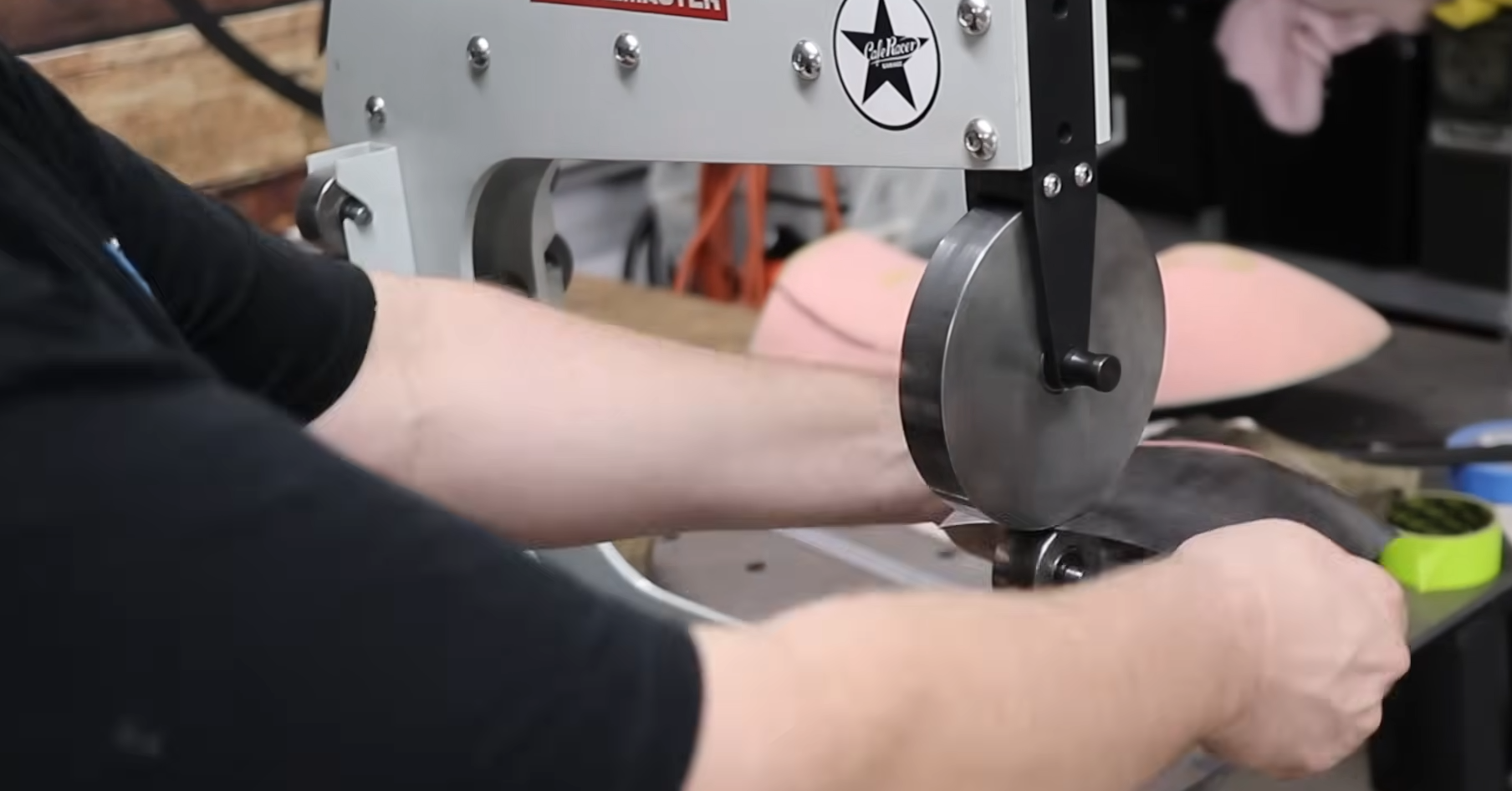

Utilizing a Curler to Add Energy

With the essential form completed, a bead curler is used to press strains into the metal. This makes the fender a lot stronger and stops it from flexing. A number of passes with the curler, and swapping out dies every time, provides each depth and energy.

Why Bead Rolling Issues:

- Provides stiffness to skinny steel

- Helps hold the fender from vibrating or bending

- Mimics basic fender types

Creating the Folded Edge and Heart Seam

The ultimate element entails tipping the perimeters and folding them over, copying the fashion of the unique Honda fender. This creates a decent seam across the exterior, boosting energy and giving a clear look.

Steps in Tipping and Seam Making:

- Use the bead curler to tip the periphery.

- Shrink corners with a foot-operated shrinker for tight bends.

- Fold the sting again onto itself for a double thickness.

Fenders are then test-fitted, with new mounting tabs tacked to the body for stability. Rubber grommets are instructed the place wires go by, and spacers will be added for a customized contact. Riv nuts or welded nuts can be utilized to mount flip indicators securely.

Methods to Connect the Rear Mud Guard

Creating Brackets and Mount Areas

To mount the rear mud guard, sturdy brackets will be made and hooked up to the bike’s body. Metallic tabs will be tacked or welded the place assist is required. These tabs ought to line up with the mud guard, permitting bolts to safe it in place. It’s useful to make use of two or extra mounting spots on the again for further stability. Present mounting holes on the bike can generally be reused for this objective.

If there isn’t any welding gear, riv nuts supply a useful manner so as to add threaded mounts. Drill holes the place wanted, insert the riv nuts, and use a rivet software to press them in. This provides a powerful spot to screw in bolts, which can be helpful for issues like attaching flip indicators.

Utilizing Modeling Clay for Measuring Gaps

A delicate modeling materials, like children’ plasterine, makes it easy to measure uneven gaps between the mud guard and the body. Press the clay into the hole to create a customized wedge. This wedge will fill the house and assist align the guard throughout mounting. The clay holds its form and is straightforward to take away, making it a lot sooner to get an accurate match in comparison with guessing or utilizing cardboard.

Under is an easy desk describing the method:

| Step | Device/Materials | Goal |

|---|---|---|

| Fill the hole | Plasterine/clay | Get actual wedge form |

| Take away and hint | Plasterine/clay | Use form for steel insert |

| Make wedge | Metallic, based mostly on clay | Fill hole with out distortion |

Making Certain the Guard Stays Sturdy and Straight

Energy is added by shaping the perimeters of the steel mud guard. Rolling or folding the perimeters again on themselves, very like the unique manufacturing unit design, makes the guard much less prone to bend or twist. This may be performed with easy steel instruments like a bead curler or planishing hammer.

Suggestions for a powerful, well-aligned mud guard:

- Use a number of passes with rolling instruments for easy, even edges.

- Shrink or stretch corners as wanted to match the curve of the bike.

- Double-check the alignment earlier than tightening bolts, utilizing spacers if wanted for a customized match.

- If drilling holes for wires, defend them with rubber grommets to stop harm.

Taking these steps will assist the mud guard look neat and maintain up nicely below use.

Tail Tidy and Quantity Plate Bracket Setup

How the Arc Droid Shapes the Quantity Plate Bracket

The Arc Droid was used to chop out the principle piece for the tail tidy, or quantity plate bracket. This bracket contains aspect tabs that may both be trimmed off or bent at a 90-degree angle for mounting flip indicators. The piece suits Australian quantity plates precisely. For these , brackets like this may be ordered on-line and are pre-cut for this objective.

A customized extension piece was additionally made so the bracket might use the pre-drilled bolt holes already current on the bike. This helps the bracket match securely and makes use of current mounting factors.

Key steps:

- Lower bracket utilizing the Arc Droid

- Tabs permit for further mounting choices

- Matches the scale of the proper quantity plate

- Added extension for current bolt holes

Customizing Tabs for Rear Flip Indicators

The tabs included on the bracket will be modified based mostly on what is required for mounting the rear flip indicators. One methodology is to drill holes within the tabs and weld them to the aspect of the bracket. An alternative choice is to weld a stainless-steel nut flush with the skin fringe of the tab, permitting the flip indicators to screw in straight.

For these with out welding instruments, riv nuts are a superb different. Riv nuts will be put in after drilling the holes and supply a powerful thread for attaching flip indicators. It’s essential to make use of rubber grommets when operating wires by metal to cease the wires from being broken.

Suggestions for flip sign mounting:

- Drill holes in tabs as wanted

- Weld nuts for screw-in mounting, or use riv nuts if welding isn’t potential

- Use rubber grommets for wiring safety

- Aluminum spacers can be utilized for a customized look

Making the Bracket Match Pre-Drilled Holes

The quantity plate bracket was designed so it might use the holes that had been already drilled within the bike’s body. This meant making an extension piece for the tail tidy. With this setup, no further holes wanted to be drilled and the match was safer.

Most inventory rear fenders have holes that can be utilized for mounting a tail tidy, so a customized bracket or an extension could also be wanted relying on every bike. This helps the setup work with completely different fender designs and makes set up easier and extra secure.

| Step | Goal |

|---|---|

| Use pre-drilled holes | Retains set up easy |

| Add bracket extension | Suits current body correctly |

| Match holes for stability | Safe bracket and plate |

Utilizing these steps, the bracket and tail tidy lined up nicely with the bike and gave a neat end with out the necessity for further drilling.

Altering the Inventory Rear Mudguard

Chopping and Adjusting the Fender

First, the unique rear mudguard must be trimmed to suit the brand new look of the bike. They mark the place it ought to be reduce, then rigorously take away the additional plastic or steel. This helps hold the fender the suitable measurement and form for the brand new construct. They use a wedge as a information to get an ideal match with the body.

Key Factors:

- Mark the brand new fender size with tape or a pencil.

- Use a noticed or reducing software for a clear edge.

- Double-check the match earlier than making any last cuts.

Making and Attaching Mounting Brackets

Customized brackets are wanted to place the fender again on the bike. They make a easy bracket from steel and weld it to the fender. For further mounting factors, drilled holes within the body or fender can be utilized.

A welding tip: maintain a chunk of copper behind any holes so the weld received’t stick; this lets the realm be crammed neatly.

Bracket Steps:

- Lower bracket materials to measurement.

- Tack weld the bracket to the fender.

- Drill holes for mounting bolts.

- Connect tabs for flip indicators by welding nuts flush or utilizing riv nuts if welding will not be obtainable.

| Methodology | Instruments Wanted | Observe |

|---|---|---|

| Welding nuts | Welder, stainless nuts | Sturdy, everlasting mount |

| Riv nuts | Rivet gun, riv nut equipment | Good for these with out welder |

Use rubber grommets when drilling for wires to cease them from rubbing.

Becoming the Plastic Interior Protect

If the inventory plastic lining from the previous fender remains to be round, it may be heated and bent to match the brand new fender’s form. Simply slowly heat the liner and press it into place. This helps hold mud and dust off the again of the seat and body.

Advantages:

- Simple to reuse the unique defend.

- Much less mess thrown up by the wheel.

- No want to purchase further components.

Inventive Approaches for Mounting Flip Indicators

Attaching Stainless Nuts as Mounting Factors

One possibility makes use of stainless-steel nuts. The nuts are welded flush to the sting of the mounting tab. This provides a powerful threaded spot to screw within the flip sign. It retains the look clear and durable. This methodology works nicely if welding is accessible.

Advantages:

- Sturdy and sturdy maintain

- Clear look

Becoming Rivet Nuts With out Welding

If welding isn’t potential, rivet nuts supply a stable different. Drill a gap the place the flip sign will go. Place a rivet nut within the gap, and use a rivet software to set it. Now, flip indicators will be screwed in securely.

Steps to Set up:

- Mark and drill the correct-sized gap.

- Insert the rivet nut.

- Use the software to lock it in place.

- Verify thread for match.

Tip: Verify if the flip indicators use M6 or M8 threads, as rivet nut kits come in numerous sizes.

Secure Wiring with Rubber Grommets

Each time wires go by steel, rubber grommets hold them protected. After drilling any holes, slip a rubber grommet into the outlet earlier than threading wires by. This stops the perimeters from reducing the wire and helps keep away from electrical shorts.

Why Use Rubber Grommets?

- Protects wires from sharp steel

- Helps forestall electrical issues

- Simple to put in

Customized Aluminum Spacers for Mounting

For a extra distinctive look, aluminum spacers will be made. Spacers match between the tab and the flip sign. They supply further house and a customized fashion. The size and measurement will be adjusted for the precise match and look wanted.

Spacer Concepts:

- Use thicker spacers for a bolder fashion.

- Paint or polish for a customized end.

- Combine sizes for a layered impact.

Tip: Check with completely different spacer sizes to seek out what suits your construct greatest.