It began with a “Tantrum.”

That’s the identify given to the Professional Touring-style 1970 Dodge Charger, a restomod accomplished by a small store in Grafton, Wisconsin, in 2015. With a low stance, carbon-fiber physique panels, an enormous 1,350-hp marine engine, and a lovely end, the Tantrum caught the attention of the producers of the “Quick & Livid” franchise when it appeared on the 2015 SEMA present, incomes it a job within the seventh installment of the sequence, “Livid 7.” From there, that Tantrum made the builder, SpeedKore Efficiency Group, one of many highest-end, most elite restomod retailers within the nation, particularly for Mopar followers.

Speedkore 1970 Dodge Charger Tantrum

“The Charger is an iconic physique model,” Tom Porter, senior enterprise improvement supervisor for the store, advised Motor Authority. “Nobody actually had achieved something as wild (as Tantrum), so when you’re going to get into the Professional Touring house you gotta are available in and also you gotta do one thing totally different.”

SpeedKore began as a ardour undertaking for Jim Kacmarcik, Chairman and CEO of Kacmarcik Enterprises. It’s a part of the Kacmarcik Group of 15 firms in southeastern Wisconsin that features Kapco Steel Stamping, an industrial coatings enterprise; the Home of Harley-Davidson; a trucking firm; a music publishing firm; and a number of philanthropic nonprofits.

Kacmarcik had labored with one other store to construct a private automotive and loved the method. He had the assets and the house to begin his personal firm, and having discovered in regards to the gamers within the automotive world within the space, he began to rent them. They included a grasp fabricator who constructed drag vehicles for many years, a grasp technician together with his personal small store, an engineer, and a physique man.

The present group consists of simply 11 staff, together with eight within the store, two enterprise improvement managers, and Lyle Brummer, an engineer who figures out how every automotive will come collectively. The combination contains older skilled guys, a number of of whom had been there at the beginning, and youthful guys, most of whom skilled at WyoTech in Laramie, Wyoming. The store’s rising popularity has drawn expertise to the corporate, making it straightforward to rent the decide of the litter.

1970 Dodge Charger Tantrum by SpeedKore Efficiency

1970 Speedkore Dodge Charger Evolution

SpeedKore

The Tantrum Dodge Charger (prime left) burts onto the scene in 2015 and earned a job in

SpeedKore: The tasks

After Tantrum, SpeedKore constructed a BMW, then a Boss Mustang, some late-model Dodge Demons, and a few late-model Mustang Shelby GT350s, creating carbon-fiber physique panels for every. The vehicles shortly drew superstar purchasers, together with actors Robert Downey, Jr. and Chris Evans, comic Kevin Hart, and Stellantis design chief Ralph Gilles.

One early undertaking made unlucky headlines. “Menace,” a 1970 Dodge Challenger constructed for Hart, wasn’t a ground-up construct, however the automotive featured a number of carbon-fiber elements, together with a singular tackle the unique twin-scoop hood. It was powered by a supercharged model of the Dodge 6.4-liter V-8 making 720 hp. In 2019, with a pal on the wheel, Hart was injured in an accident that put him within the hospital for 2 weeks.

Whereas the corporate has accomplished 40-50 builds with various ranges of labor, the principle sights are the six ground-up builds SpeedKore has created, all of them Chargers. The vehicles made information however for a greater motive. They had been merely lovely restomods that caught the eye of present judges. The vehicles received main awards from Goodguys, the SEMA present, and the Automobile Craft Summer season Nationals, and that earned them a number of tales within the automotive media.

“Our DNA within the model was developed within the Mopar house,” Porter mentioned. “The Tantrum was actually the automotive. We invested rather a lot by way of a producing enterprise within the tooling for the carbon fiber for that sort of automotive, for the ’68 by ’70 B-body vehicles.”

These B-body vehicles embrace the Dodge Charger and Coronet and Plymouth Satellite tv for pc, GTX, and Highway Runner, amongst different much less thrilling vehicles, however SpeedKore actually specializes within the Charger.

After Menace got here a second 1970 Charger known as “Evolution.” The thought this time round was to go along with a full carbon-fiber physique on a ground-up undertaking. It sports activities the Demon’s supercharged 6.2-liter V-8 that sends its 840 hp by a 6-speed handbook transmission.

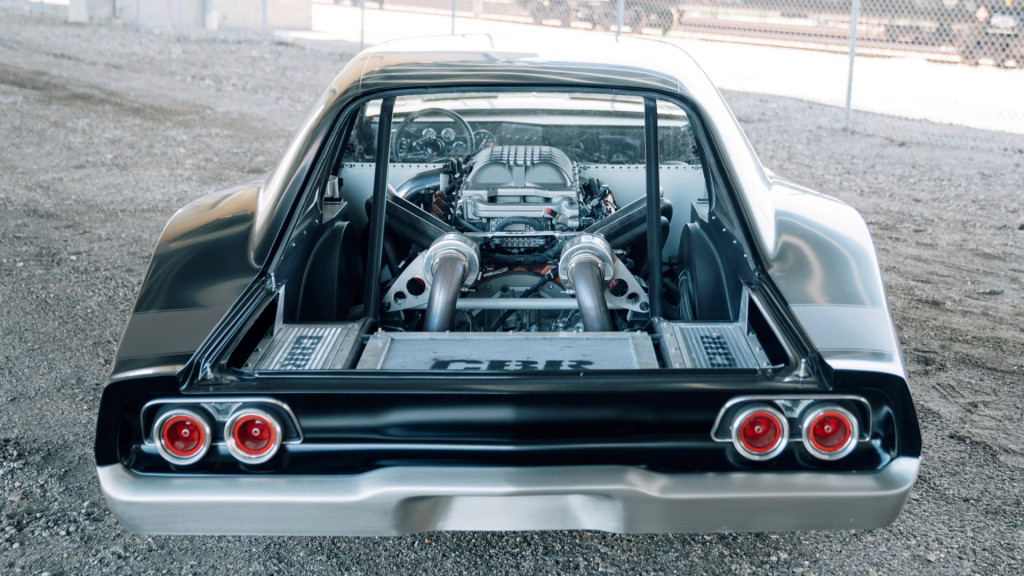

The “Quick and Livid” franchise got here calling once more, commissioning a automotive for 2021’s “F9: The Quick Saga.” Referred to as “Hellacious,” the automotive is a mid-engine 1968 Charger, and it stays essentially the most radical automotive the store ever constructed. It has a wide-body design, a big glass rear window that reveals off the mid-mounted supercharged 6.2-liter Hellcat V-8, and a sparse inside with low-back bucket seats. SpeedKore designed the chassis, incorporating a Detroit Pace double A-arm entrance suspension with a rear cradle from Race Automobile Replicas. The engine sends its energy to the rear wheels by a Graziano transaxle from a Lamborghini Gallardo.

Hart did enterprise with the store as soon as once more, commissioning a 1970 Charger known as “Hellraiser.” It boasts a Mopar Hellephant supercharged 7.0-liter V-8 spitting out 1,000 hp and 950 lb-ft of torque.

Gilles, the chief design officer at Stellantis, labored with SpeedKore to construct a 1968 Charger of his personal. Referred to as “Hellacious,” it additionally sports activities Hellephant energy.

The newest ground-up undertaking is a 1970 Charger known as “Ghost.” The one full carbon-fiber-bodied automotive to put on a full paint job, the automotive takes its identify from the white end. It groups a Hellcat V-8 with a 6-speed handbook transmission.

SpeedKore Hellucination 1968 Dodge Charger

SpeedKore Ghost 1970 Dodge Charger

More moderen builds embrace the (counterclockwise from prime) Hellucination, Ghost, and Hellraiser Dodge Chargers.

SpeedKore: Professional Touring aesthetic

SpeedKore builds have a clear Professional Touring look. The corporate’s customized body pushes them low to the bottom. The our bodies are principally inventory, however with the drip rails typically shaved. They’re tubbed and sit on broad and wider tires wrapping HRE 19- and 20-inch wheels with a contemporary look. Most showcase their darkish carbon-fiber physique work below a transparent coat, however prospects are free to color them any coloration they need. They give the impression of being inventory however sinister, like the best way a efficiency model of a classic Charger would look if it had been constructed at the moment to deal with a street course.

“We don’t need massive blowers protruding of the hood and issues like that. That’s not us, that’s not our model,” mentioned Porter. “When you’re coming to us, you’re on the lookout for a really, very tight, unique wanting automotive.”

“Each automotive can have its personal persona round what the client needs,” Porter famous. “For instance, ‘I would like an AAR hood, and so forth.’ So long as we don’t bastardize it. The forefathers in 1968, ’69, and ’70, they knew. These vehicles, they’re iconic.”

The look caught the attention of Gilles at an LX Springfest a number of years in the past. Gilles advised Motor Authority he was interested in how understated the automotive was.

“From a distance, it seemed like a really properly achieved, lowered, type of a restomod theme however very clear. And the nearer I acquired to it, it revealed the carbon fiber, and the small print, and I seemed inside and I simply couldn’t recover from how effectively made it was,” Gilles mentioned.

The store will create a rendering for a buyer and has labored with designers, together with Sean Smith (who designed Tantrum when he labored on the store), Rami Curry, and Gilles. Gilles designed the hood scoop of his 1968 Charger to suit the Hellephant V-8 within the engine bay, and he additionally designed the wheels on his automotive as a contemporary tackle the Hurricane wheels of the Common Lee 1968 Charger from “The Dukes of Hazzard.”

SpeedKore Hellraiser 1970 Dodge Charger

1970 Speedkore Dodge Charger Evolution

The retro-modern interiors of the (counterclockwise from prime) Hellraiser, Evolution, and Hellucination Dodge Chargers.

The interiors aren’t as inventory, however they’ve a clear, purposeful, and high-quality aesthetic of their very own. SpeedKore designs the look in-house and works with the oldsters on the California store Gabe’s Avenue Rod Customized Interiors, Auto Alliance in Appleton, Wisconsin, and the upholstery firm Katzkin for upholstery. The dashboards are fashionable takes on the originals, typically achieved in carbon fiber, and the middle consoles are broad and tall to suit the drivelines within the lowered our bodies. Trendy bucket seats with or with out full racing harnesses often exchange the flat seats of yore. The corporate has its personal branded retro-modern gauges made by Basic Devices, switchgear is commonly constructed from billet aluminum, and most builds embrace a Kicker audio system.

After driving his automotive, Gilles appreciates one other side of SpeedKore’s design. “The best factor they do this they don’t get credit score for is that they (flush)mount the windshield like a contemporary automotive. In order that they do away with the massive seals.” Gilles famous that this little element actually updates the look and likewise makes the automotive quiet from behind the wheel.

SpeedKore store tour

SpeedKore store tour

A 1970 Plymouth Barracuda on the rotisserie for paint prep and set up of warmth protect within the tunnel and sound deadener within the flooring. That carbon-fiber flooring can also be proven, as is a carbon-fiber hood.

SpeedKore: Hand-built avenue machines

Whereas each full SpeedKore construct has a VIN, nearly nothing from an unique muscle automotive makes it to the ultimate product. Meaning the donor automotive doesn’t must be in good condition. It simply wants a number of the unique’s primary geometry. It’s wonderful to take a look at how a SpeedKore automotive begins and the way it finally ends up. The store makes use of Mopars5150 to supply its vehicles. That firm scours the net for Mopars, and has 300-400 vehicles with clear VINs, Porter famous. “We purchase their worst of the worst,” he quipped.

A 1970 Roadrunner, 1970 Charger, two Plymouth ‘Cudas and a Pontiac Firebird within the again lot at SpeedKore awaiting their restomod fates.

SpeedKore disassembles a donor automotive, acid dips the physique, and cuts away every part however the firewall, A-pillars, roof, rear pillars, bundle tray, and the within of every rear fender panel in entrance of the rear wheels. The roof and rear pillars are additionally simply interior constructions that will likely be changed, often with carbon fiber. The unique body is minimize out, an X-truss is welded within the shell, and the automotive is placed on a SpeedKore body. Porter estimates that simply 5% of the unique automotive stays.

SpeedkorThis is all that is left of a 1969 Dodge Charger donor automotive as soon as SpeedKore has stripped away every part it would not want.e store tour

That is all that is left of a 1969 Dodge Charger donor automotive as soon as SpeedKore has stripped away every part it would not want.

That is all that is left of a 1969 Dodge Charger donor automotive as soon as SpeedKore has stripped away every part it would not want.

SpeedKore makes carbon-fiber physique panels for the 1968-70 B-body Mopars to be used on undertaking vehicles, promoting them by its on-line retailer. It additionally provides bumpers, splitters, and different elements for classic and late-model Dodge, Plymouth, Ford, and Chevrolet fashions. Its carbon-fiber Dodge Challenger elements can be found by Path Connection. The corporate additionally makes Harley-Davidson fenders, headlight bezels, aspect covers, and different trim elements, and sells them on-line and thru Harley sellers.

The ultimate construct high quality of the Charger physique panels is healthier than something that got here from the manufacturing facility. That’s not saying a lot as a result of Mopars within the muscle automotive period had been recognized for poor match and end.

To make its physique panels, SpeedKore first scans three variations of a B-body automotive and averages the ends in CAD, making changes for the very best match part-to-part. Smaller elements might be 3D scanned or created in CAD.

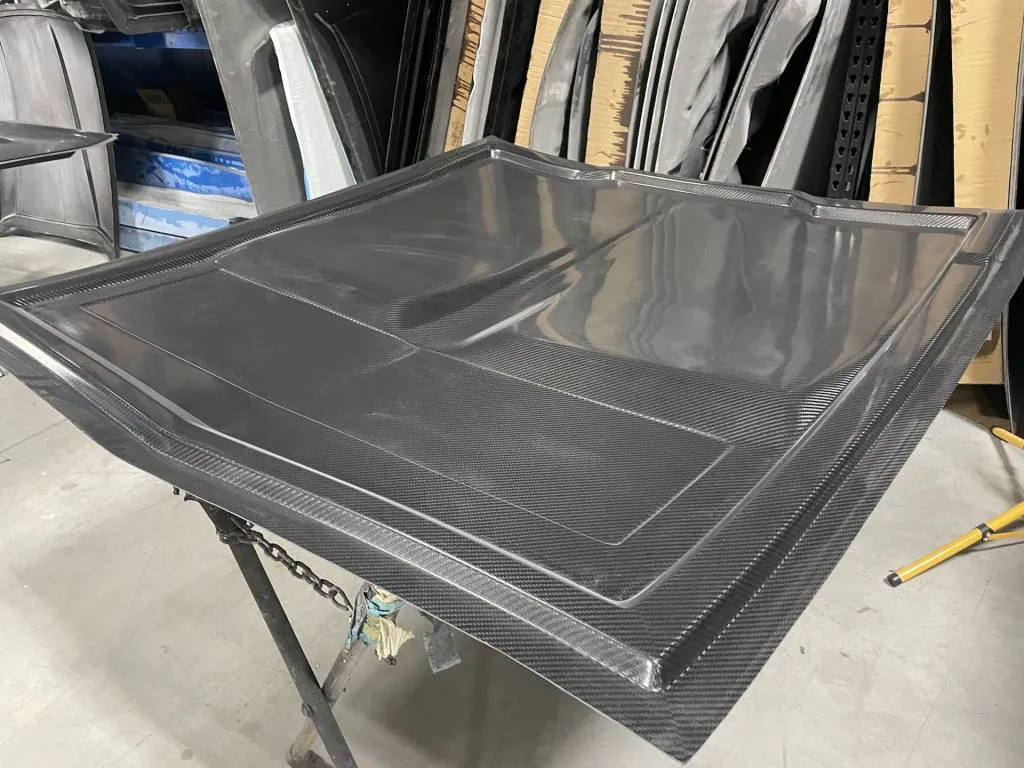

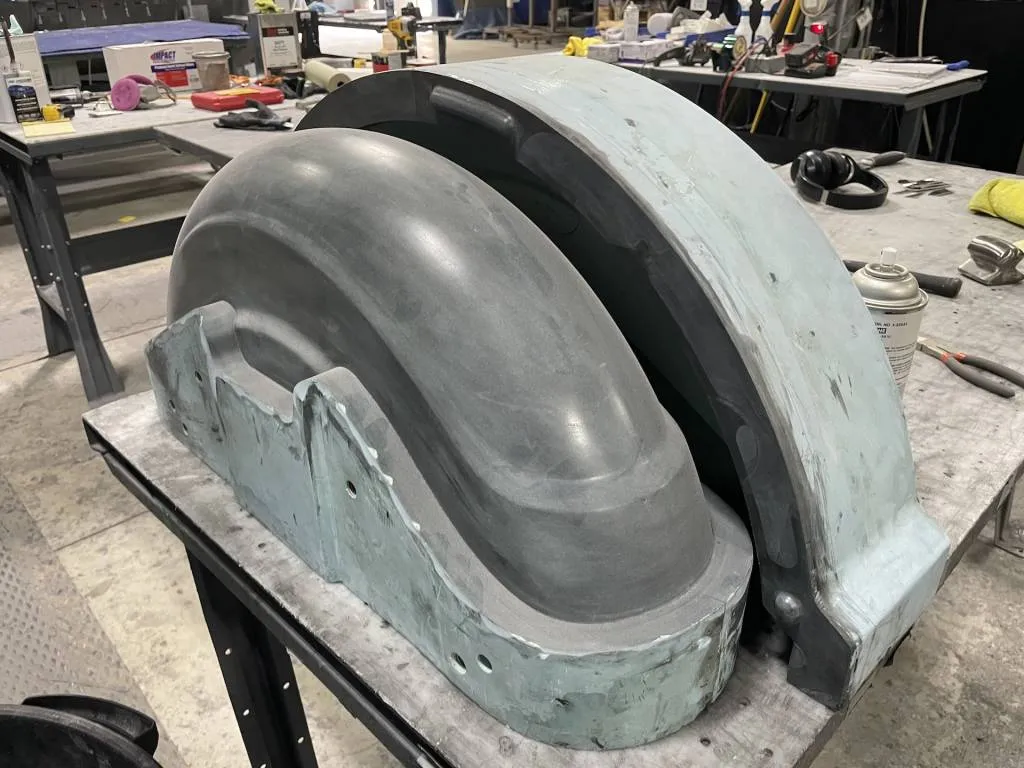

The CAD knowledge is then used to make a plug that can serve the grasp type of the ultimate half. Constituted of a composite materials and CNC machined to form, the plug is produced by a vendor. When it comes again, it’s sealed, prepped, and cured. It’s now able to act because the grasp half form from which pre-impregnated carbon-fiber molds are made.

The mould is the damaging of the half and it’s created off of the plug from layers of pre-preg. One mould could make about 20 elements. The method is illustrated beneath with the grasp, plug, mould, and remaining product of a Harley-Davidson fender. The store’s warehouse is stuffed with molds, and with every one the staff learns tips on how to make higher and higher elements, Porter mentioned.

Carbon-fiber elements are created by first making a grasp or plug (first picture), then making a mould off of it (second picture), laying within the carbon fiber, then trimming it. These fenders are for a Harley-Davidson bike.

Carbon-fiber elements are created by first making a grasp or plug (first picture), then making a mould off of it (second picture), laying within the carbon fiber, then trimming it. These fenders are for a Harley-Davidson bike.

Carbon-fiber elements are created by first making a grasp or plug (prime), then making a mould off of it (backside left), laying within the carbon fiber, then trimming it. These fenders (backside proper) are for a Harley-Davidson bike.

Pre-preg is available in rolls and consists of the carbon-fiber weave impregnated with a resin that helps the ultimate half take its form. The rolls are saved in freezers till they’re prepared for use.

When it’s time to make a component, a fender as an illustration, digital data is used to flatten the fender geometry, and a template is created to chop the fabric to dimension. A typical fender will consist of 1 piece in 5 layers match into the mould. Thinner materials is used for the primary two beauty layers, and they’re backed by three layers of fabric which can be every about 4 occasions as thick.

The carbon-fiber layers are laid right into a mould and pushed into the cracks, crevices, and angles by hand. The half is then bagged and related to a vacuum to suck the carbon-fiber extra exactly into the mould, a course of known as debulking.

SpeedKore’s autoclave can maintain elements as much as 13.5 ft lengthy.

The bag is then put into an autoclave, which is basically a giant oven that additionally introduces stress. The vacuum is then reattached, temperature sensors are hooked up, and the autoclave cycle is run. A typical cycle will final three hours at about 200 levels. When the cycle is completed, the half and mould are pulled out collectively, debagged, and the mould is break up, sometimes with air, to take away the half from the mould. The piece is then evaluated and any sharp edges are trimmed. Utilizing prepreg for each the half and the mould means they react the identical to the temperatures of the autoclave. Porter says the corporate’s autoclave can maintain a component as much as 13.5 ft lengthy.

Weave orientation on the beauty layers is vital. SpeedKore makes positive the weave orientation from the left entrance fender to the hood to the entrance bumper to the appropriate entrance fender to the doorways all matches up completely. That is achieved digitally, and the roll of pre-preg is rotated to get the appropriate minimize.

SpeedKore tries to be true to the unique, so physique brackets will match the identical method in the identical spots, although they might even be constructed from carbon fiber.

The whole physique is assembled on the automotive, and will or is probably not painted. Most patrons need to showcase their carbon fiber both below a transparent coat or a darkened clear coat. The store has its personal paint sales space to create a glass-smooth end.

SpeedKore makes its 1968-’70 Dodge B-body body from 12-gauge metal and assembles it on a body jig.

SpeedKore store tour

SpeedKore makes its 1968-’70 Dodge B-body body from 12-gauge metal and assembles it on a body jig.

The physique suits on a customized B-body body designed by SpeedKore. It provides the vehicles a low stance and leaves room for tubbed rear wheels. The body’s 12-gauge metal is laser minimize by Kapco throughout the road, and each bit has tabs for fitment. Boxed and welded, the frames are assembled on a jig and designed so the gas and oil traces match inside their tubing. Thus far, SpeedKore solely has a B-body body, however the firm is engaged on an E-body body for 1970-74 Dodge Challengers and Plymouth Cudas.

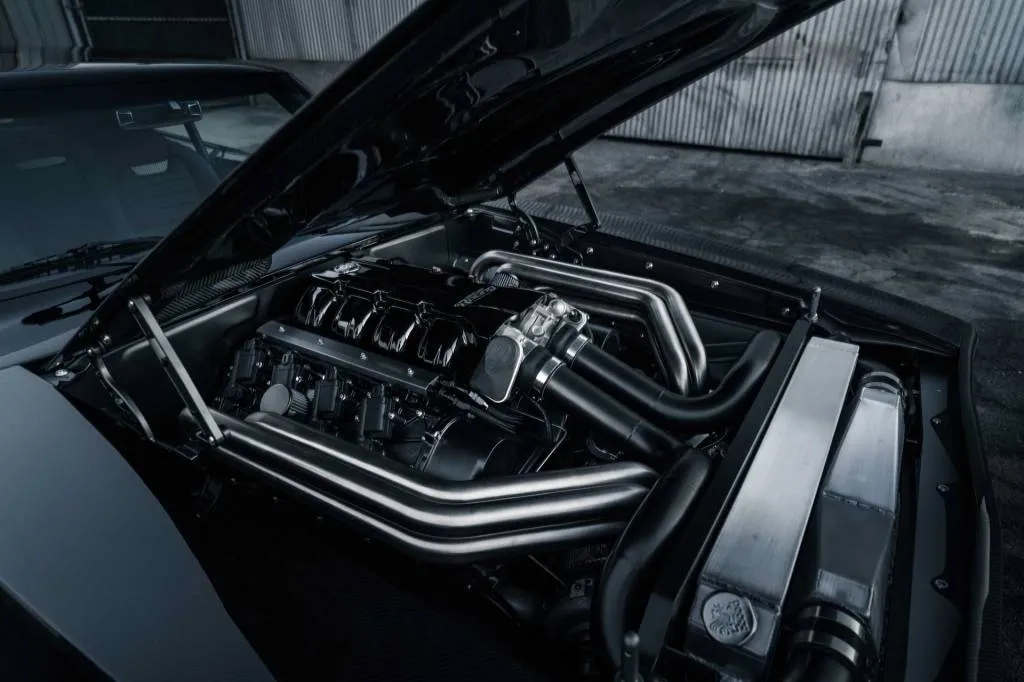

Engines are chosen by every particular person purchaser, and SpeedKore often works with Mopar crate engines which can be basically plug-and-play without having for tuning. The store has used Demon, Hellcat, and 392 engines, and Hellephant engines. “Our buyer can drive our automotive right into a dealership they usually can run diagnostics on it,” Porter mentioned.

Tantrum’s Mercury marine twin-turbocharged 9.0-liter V-8 makes 1,350 hp on pump fuel.

The engine in Tantrum was distinctive, although. It was a QCV4 Mercury Racing marine engine. A twin-turbocharged 9.0-liter V-8, it put out 1,350 hp on pump fuel or 1,650 hp on 110-octane fuel. That energy is fed to the rear wheels by a Tremec 6-speed handbook transmission and a Ford 9-inch rear finish.

SpeedKore is aware of the engines will match and the vehicles will go collectively effectively because of know-how and pre-planning. “We digitally construct the vehicles to a excessive diploma earlier than we assemble them,” Porter mentioned. The staff 3D bluelight scans the engine, the engine bay, and the engine pickup factors to preplan how every part will go collectively. The ultimate outcome makes for a tidy engine bay that’s jewellery in itself.

Along with the body, SpeedKore has its personal 4-link rear suspension. The store often works with Detroit Pace for the entrance suspension, and brakes can come from Brembo, Willwood, Baer, or another supply of the shopper’s selection. A 14-point roll cage is often built-in for rigidity and security.

Along with the 3D scanner, the store has a full array of instruments to perform any job, together with mills, lathes, 3D printers, and an English wheel. The store additionally has its personal paint sales space and grinding sales space. About half of the 3D-printed elements are made in-house and the opposite half are despatched out to distributors. Billet elements might be designed in-house and despatched to distributors as effectively. For milling and machining tasks, the store will design the half, akin to a metallic grille, and will even program the tooling path, however it is going to ship out the info to chop the half, typically to Kapco.

SpeedKore works on about 4 vehicles per 12 months, and the store would possibly end one or two. The vehicles can take as much as three years to construct and every has 5,000 or extra hours of labor in it.

SpeedKore Hellucination 1968 Dodge Charger

SpeedKore Hellucination 1968 Dodge Charger

SpeedKore Hellucination 1968 Dodge Charger

SpeedKore: Present and go

With their V-8 energy, SpeedKore vehicles are clearly quick. Nonetheless, they’re constructed to show corners as effectively.

“The vehicles are low, they’ve an amazing turning radius, full clearance lock to lock,” Porter mentioned. “The vehicles deal with nice. You may drive them throughout the nation. You may monitor ’em. We wish folks to have a efficiency automobile expertise.”

Gilles took SpeedKore up on that promise, taking supply of Hellucination at GingerMan Raceway in Western Michigan. He ordered the automotive with two units of wheels and tires, together with a set of slicks and a set of Michelin Pilot Sport Cup tires, and put it by its paces with temperatures within the 90s. Porter says Gilles did six to eight laps as a shakedown and SpeedKore adjusted the automotive’s tune for the monitor.

“We don’t use the time period race automotive, however they’re like a Trans Am race automotive. That automotive geared proper is able to 200 mph,” Porter mentioned.

Gilles’ response to the automotive on the monitor?

“I used to be pleasantly stunned at how the automotive dealt with. It doesn’t deal with like a ’68 in any respect. It handles way more like a contemporary automotive. Loads of grip, quite a lot of braking energy. Tons of torque. I imply you barely contact the pedal and the factor is launching you,” he mentioned.

“The automotive felt very gentle and agile. The automotive is effectively below 4,000 kilos, so it is fairly enjoyable to drive. I used to be beaming the entire time.”

Hallucination doesn’t have traction management or stability management, however that wasn’t a priority for Gilles. “You respect the automotive. Nothing scares me, however the automotive scares me not as a result of it’s tough to drive however as a result of I’ve a lot into it, you realize ardour, my coronary heart and soul, time—it took three years to construct the automotive.”

Gilles mentioned he put 6,550 miles on his automotive in only one 12 months. He additionally mentioned that the match and end is great. “It’s as superbly designed beneath as it’s on prime.”

Gilles famous, nonetheless, that the vehicles are made for Vehicles and Espresso occasions, in order that they’re not fairly completed for normal use. “They don’t use quite a lot of LocTite, they use anti-seize on most of all their bolts. So I needed to. I took the automotive type of half aside and I put LocTite on every part as a result of I needed it to remain cinched on and torqued whereas I drive it as a lot as I do. So, I needed to type of, let’s say, street prep it,” he defined.

Whereas Gilles doesn’t even know the way a lot he spent for his automotive as he paid in a number of installments as work progressed, this type of care and energy doesn’t come low-cost.

If you must ask, it’s too costly. Determine seven figures. Don’t have a tantrum if that’s out of your finances. Given the wonder and functionality of the vehicles, plus the 1000’s of hours of hand-built experience, that appears value the fee.