The evolution of EV battery know-how displays a mix

of historic developments, rising improvements, and market

calls for.

The lithium-ion battery — now synonymous with electrical

autos (EVs) and out there commercially since 1981 — took a

whereas to catch on in automotive circles. The primary EV had a lead

acid battery and was developed a full 100 years earlier by Gustav

Trouvé in 1881.

Certainly, by 1900, of the 4,192 autos produced within the US that

yr, 1,575 (38%) had been electrical. Automobile speeds had been low at that

time and a lead acid battery was enough to present 100 miles of

vary. Nevertheless, as car speeds elevated and necessities

modified, the lead acid battery was not enough. EVs

shortly fell by the wayside as the interior combustion engine (ICE)

dominated.

Then in 1996, Common Motors (GM) — performing upon a California

Air Assets Board (CARB) mandate for zero-emission autos

(ZEVs) — launched its first era EV1. This car

once more had a lead acid battery. Like its EV counterparts earlier in

the century, the EV1 couldn’t stand toe-to-toe with ICE

rivals because the lead acid battery lacked the vitality density

(volumetric and gravimetric) to compete. Even the second era

EV1, this time with a extra energy-packed nickel metallic hydride

battery, couldn’t compete with the ICE.

These developments befell with lithium-ion as a bystander,

regardless that it offers as much as 3 times the vitality density

(volumetric and gravimetric) of lead acid and roughly two

occasions the density of nickel metallic hydride.

Similtaneously GM was tinkering with the EV1, in Japan

Nissan launched the Altra EV in 1998 to little fanfare. The Altra

is important in that it was the primary EV geared up with a

lithium-ion battery. It by no means caught on. It was not till the

lithium-ion-equipped Tesla Roadster was launched in 2008 {that a}

fireplace was lit beneath the EV market and lithium-ion grew to become

mainstream.

The principle lithium-ion battery chemistries

That’s not the place the story ends with lithium-ion. The phrase

“lithium-ion” is definitely catchall for numerous cathode (a battery's

constructive electrode) chemistries involving lithium. Materials for the

anode (the unfavourable electrode) is fairly set, with graphite

universally accepted as the fabric of selection, albeit with silicon

more and more added to the combination to enhance vitality density on the value

of a lowered cell cycle life.

Within the first purposes of lithium-ion, the cathode chemistry

selection was between lithium together with oxides of nickel,

cobalt or manganese. Nickel was favored for its vitality density,

cobalt for its reversibility, and manganese for its security. Now, in

lithium-ion batteries of this sort, a cathode combining all three

in various ratios — NCM — is favored due to the

attribute trade-offs famous above.

Till comparatively not too long ago, the NCM ratio was primarily 1:1:1.

Nevertheless, with the will to scale back value and enhance sustainability

(as a result of environmental considerations over cobalt mining) and vitality

density, the nickel ratio has been elevated to the purpose that NCM

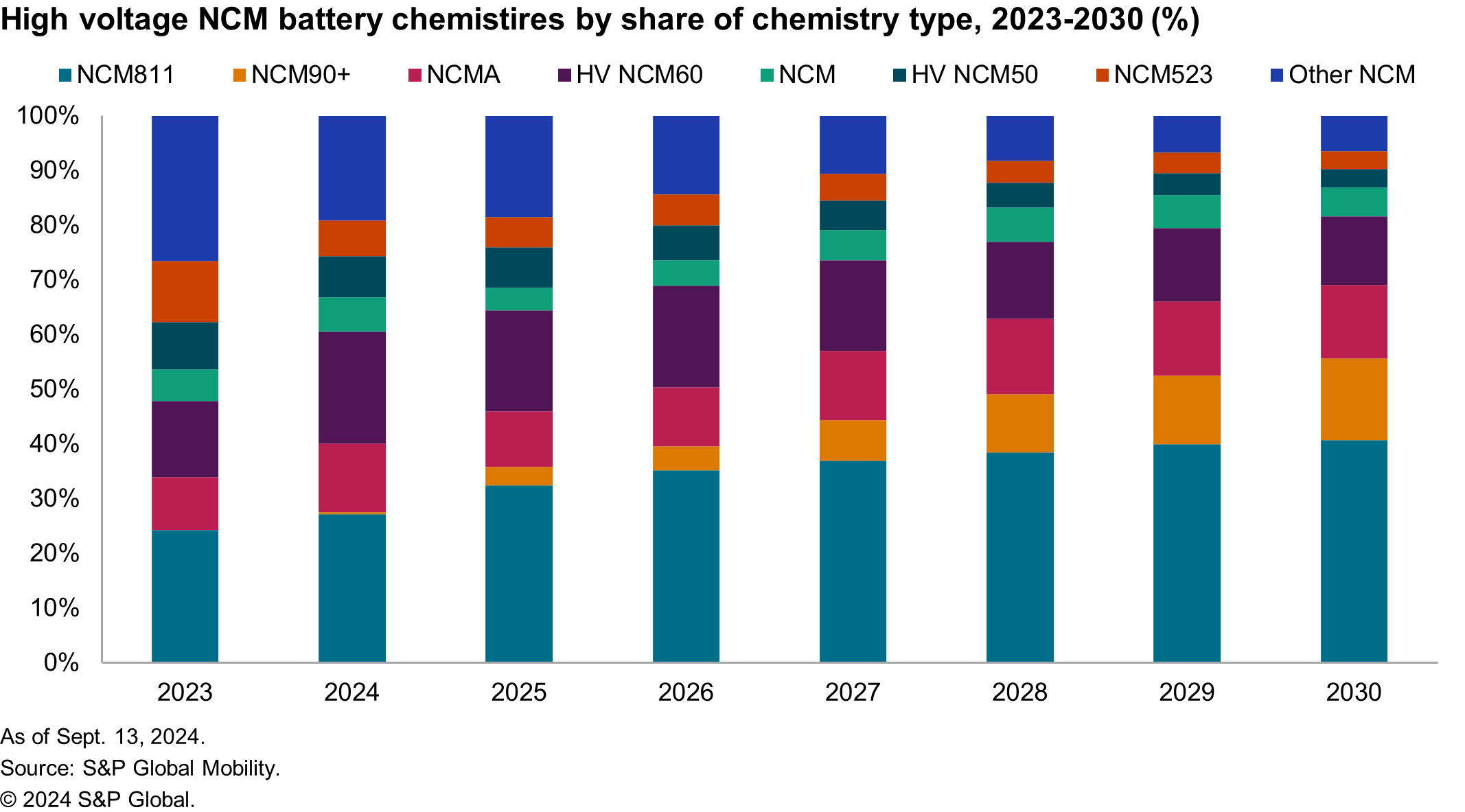

811 (8:1:1) has reached close to ubiquity within the NCM kind. The graph

beneath exhibits the market make-up and forecast for the assorted NCM

combos.

The NCM811 mixture holds sway over the market and can

progressively enhance its share. The so-called NCM90+, NCMA and HV

NCM60 chemistries are additionally of be aware. NCM90+ denotes cathodes the place

the cobalt and manganese content material is minimize additional (typical ratios can

be 9:0.5:0.5 therefore the 0 within the nomenclature) to enhance vitality

density. NCMA batteries take the premise of the NCM battery and add

aluminum to the combination for higher vitality density.

All of the above principally pertains to lithium-ion batteries of the NCM

kind (with a passing point out of NCA – nickel, cobalt, aluminum).

Including additional complexity has been the appearance of LFP (lithium iron

phosphate) lithium-ion batteries, a lot favored by Chinese language OEMs for

their decrease value, enhanced thermal stability and the widespread

availability of iron phosphate cathode supplies. These attributes,

along with the expiration of patents for LFP batteries in 2022,

have seen heightened curiosity within the chemistry exterior of Mainland

China with European and North American-based OEMs constructing LFP

provide chains.

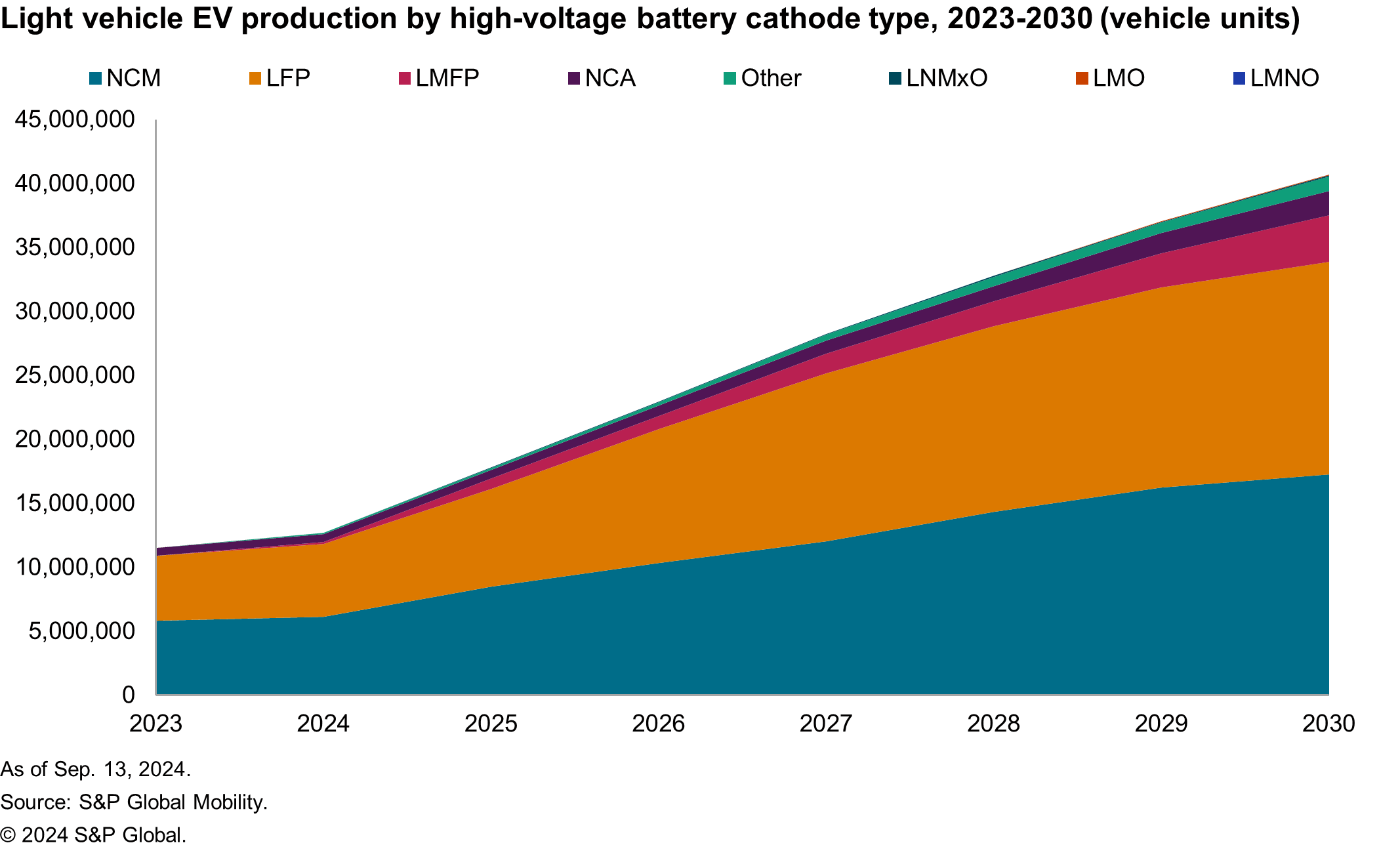

As of now, LFP and NCM — of their numerous guises —

dominate EV lithium-ion battery chemistries. In 2024, they’re

forecast to account for 94% of sunshine car EVs produced

globally.

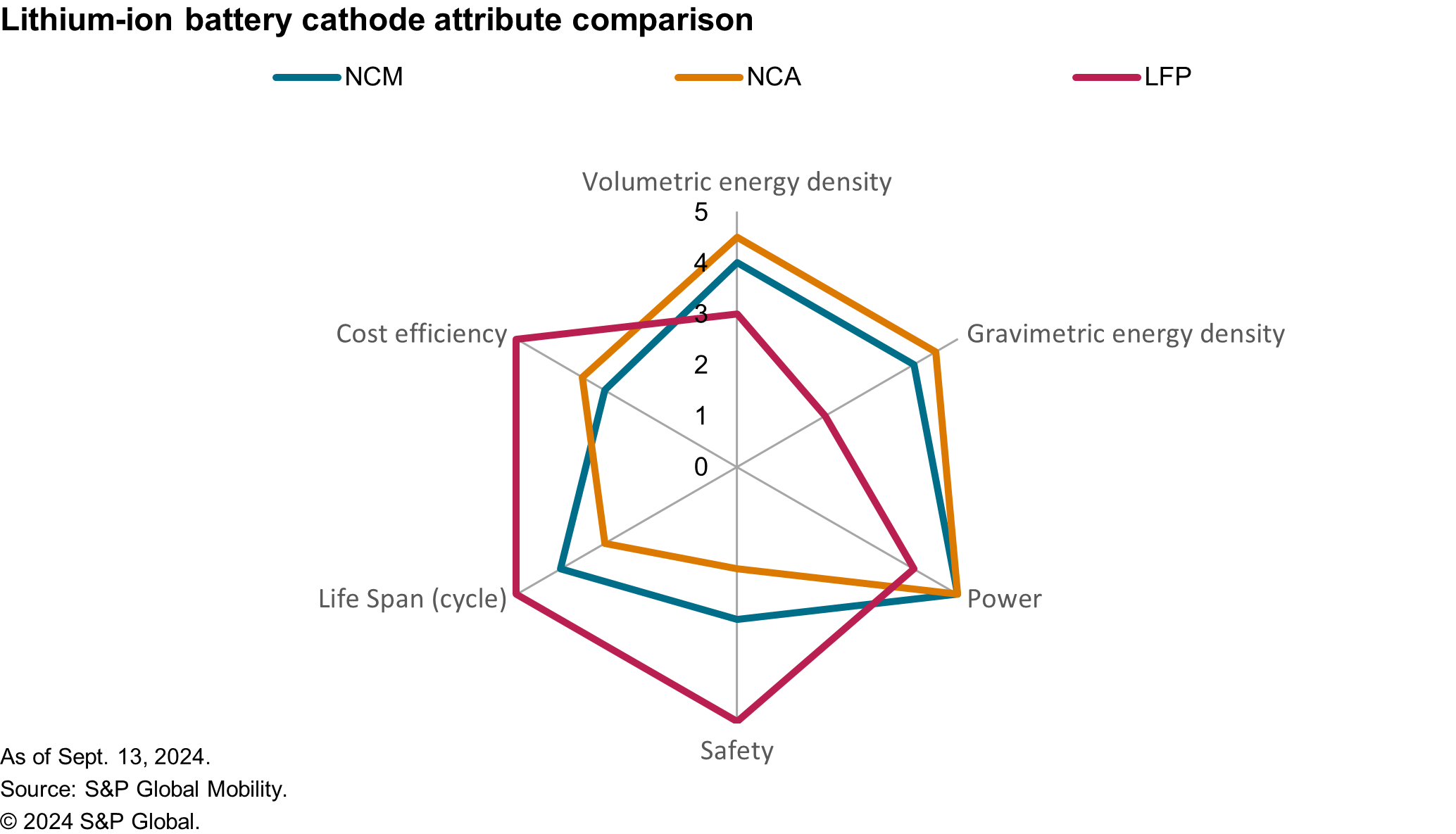

The next chart demonstrates the attribute trade-off between

all the principle competing cathode varieties for lithium-ion batteries.

Writ giant are the benefits that LFP has over competing

chemistries. Nevertheless, it falls quick in vitality density on each

gravimetric and volumetric measures, which means that bigger LFP

batteries are required to attain the identical vary, significantly when

in contrast with NCM and NCA varieties.

This shortcoming makes LFP batteries extra appropriate for gentle

autos in smaller segments and in these autos the place

efficiency is much less of an identifiable model attribute. Nevertheless,

these shortfalls mustn’t detract from the general contribution

that LFP batteries will make in electrifying gentle car fleets,

and they are going to be — and have been — a vital consider

constructing momentum in additional price-sensitive areas of the market.

What of sodium-ion and solid-state

batteries?

As gross sales development charges for EVs have not too long ago stalled in main

markets, consideration is shifting to 2 rising battery applied sciences

— sodium-ion batteries (SIBs) and solid-state batteries (SSBs)

— which will assist revitalize the trade and deal with limitations

of present applied sciences.

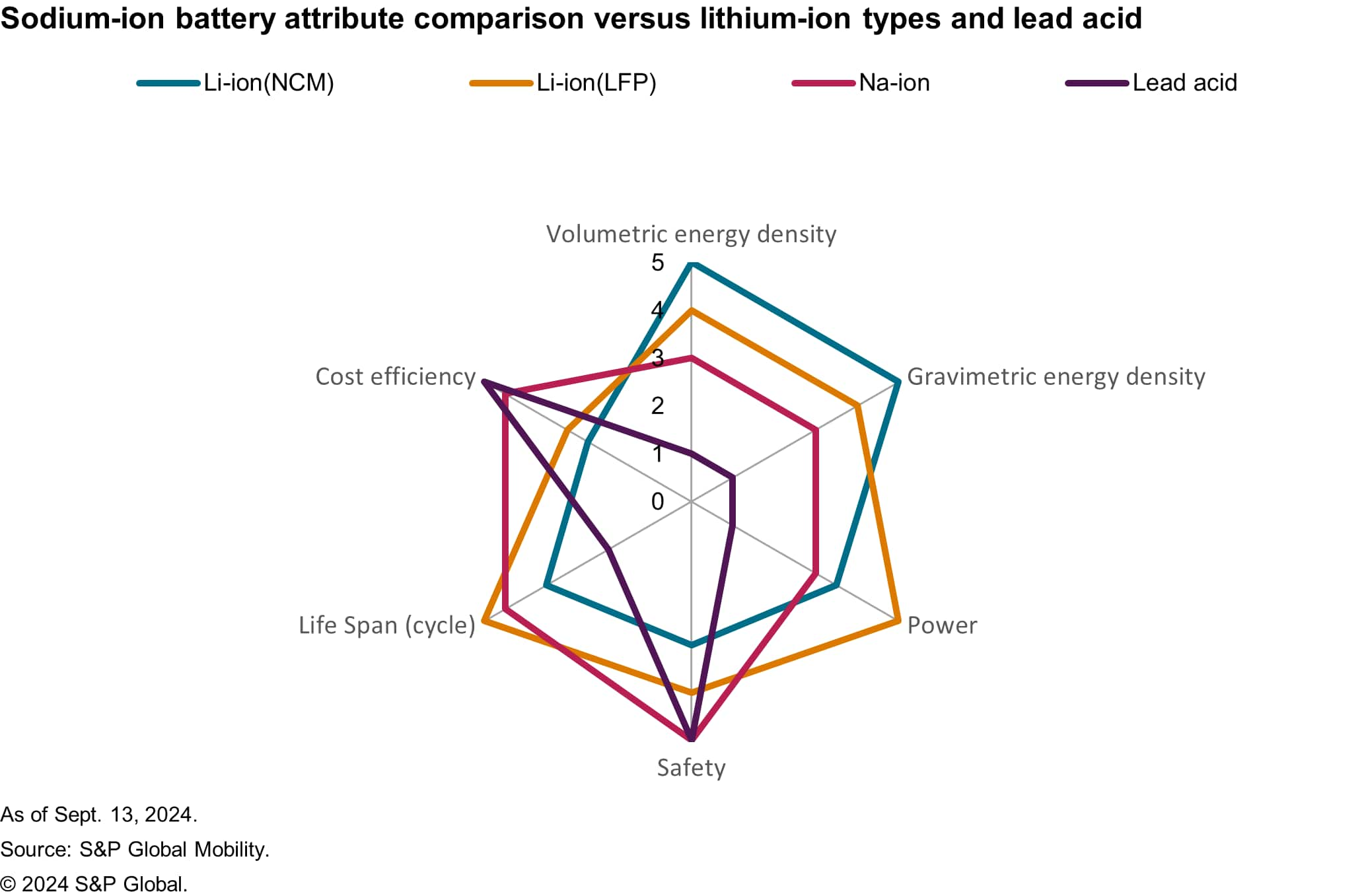

Because of the abundance of sodium in contrast with lithium, SIBs

current a probably cheaper different to lithium-ion batteries,

together with lithium iron phosphate (LFP) varieties. They keep away from the

complicated provide chains required for lithium-ion mass manufacturing.

Initially, SIBs had been seen as appropriate just for vitality storage

methods or low-performance two-wheelers. Though these segments

can be the place SIBs can be primarily used, latest developments

counsel there’s a area of interest inside gentle autos that SIBs can cater

to.

SIBs are more likely to compete with LFP batteries, as their vitality

density is roughly 160 Wh/kg, in comparison with round 200 Wh/kg

for LFP. This decrease vitality density, alongside a shorter life cycle,

limits SIBs primarily to low-cost, entry-level autos.

Nonetheless, a number of components might drive higher adoption of

SIBs within the light-vehicle sector. Technologically, SIBs are safer,

being much less liable to thermal runaway, which may result in fires.

Sodium's decrease reactivity reduces dendrite formation, a standard

failure mode in lithium-ion cells. Furthermore, SIBs can function

effectively over a wider temperature vary, offering higher

efficiency in cooler situations.

The first benefits of SIBs lie of their materials prices.

Based on S&P International Mobility analysis, the fabric value

for SIBs is about 28% decrease than LFP batteries. Moreover, SIB

manufacturing processes are almost an identical to these of

lithium-ion cells, which means that suppliers can transition with

minimal funding.

Regardless of their promise, SIB know-how remains to be in its infancy

throughout the gentle car market. Whereas restricted manufacturing started in

Mainland China this yr, forecasts counsel SIBs will obtain solely

low single-digit market penetration by 2030.

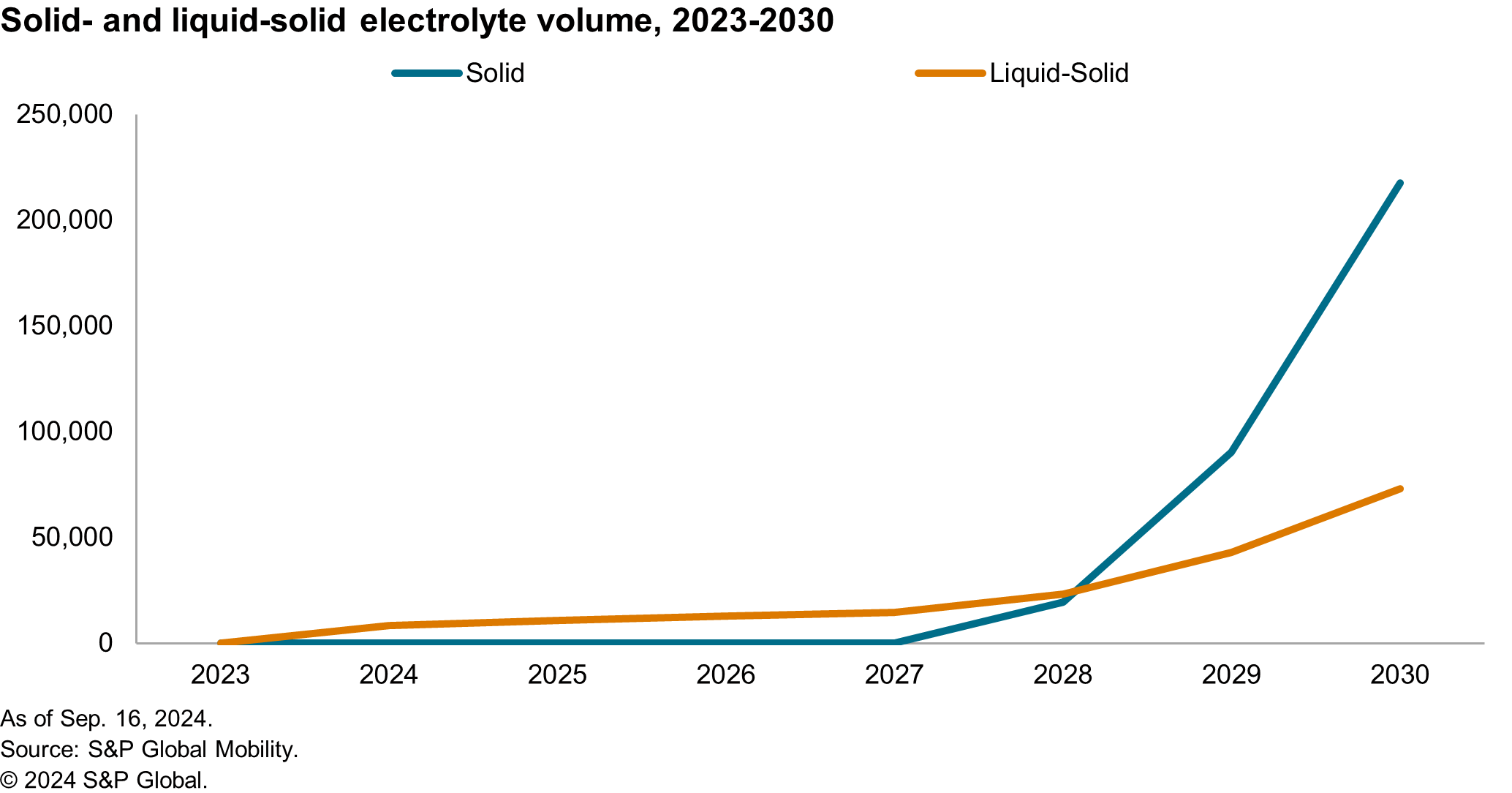

The second know-how value contemplating is solid-state batteries

(SSBs), which basically alter lithium-ion battery design by

changing liquid electrolytes with strong ones. This transition is

complicated, with interim options involving semi-solid and

almost-solid electrolytes additionally thought-about for growth.

SSBs provide three important advantages. First, they improve

security; current liquid and gel electrolytes are extremely flammable,

particularly when used with high-nickel cathodes, that are much less

thermally secure.

Second, when paired with lithium metallic anodes, SSBs can obtain

vitality densities 50%-80% increased than conventional high-nickel

lithium-ion cells, permitting for higher car vary. For instance,

Nio not too long ago launched its ES8 with a 150-kWh semi-SSB, boasting an

vitality density of 360 Wh/kg and a spread of 930 km on the Chinese language

check cycle — about 20% greater than the most effective present lithium-ion

battery.

Nevertheless, SSBs aren’t fully risk-free; they will nonetheless undergo

thermal runaway beneath excessive situations or injury, and the melting

level of lithium (180°C) poses challenges.

Regardless of these benefits, a number of hurdles exist for SSB

adoption. Using lithium metallic anodes, which may result in uneven

plating and dendrite formation, poses dangers to battery integrity.

Moreover, strong electrolytes are much less conductive, probably

limiting energy output, particularly in colder situations. In some

circumstances, exterior heating is critical, significantly with polymer

electrolytes.

Furthermore, current gigafactories designed for lithium-ion

battery manufacturing would require important re-investment to

accommodate SSB manufacturing, complicating the transition. S&P

International Mobility estimates that by 2025, SSB prices can be round

$500 per kWh — over 5 occasions the price of lithium-ion

batteries. Which means SSB packs will initially be extra

costly even with increased vitality density.

Whereas some analysis signifies potential value benefits for

SSBs, they are going to stay pricier than lithium-ion batteries within the

short- to medium-term. S&P International Mobility forecasts that

preliminary SSB purposes can be in premium battery-electric and

hybrid autos, the place the higher vary promised by SSBs is a

important promoting level. Higher China and Europe will lead SSB

manufacturing, accounting for over 73% of the forecasted 2.3 million

SSB autos by 2034, with main automotive manufacturers like

Mercedes-Benz and BMW dominating the output.

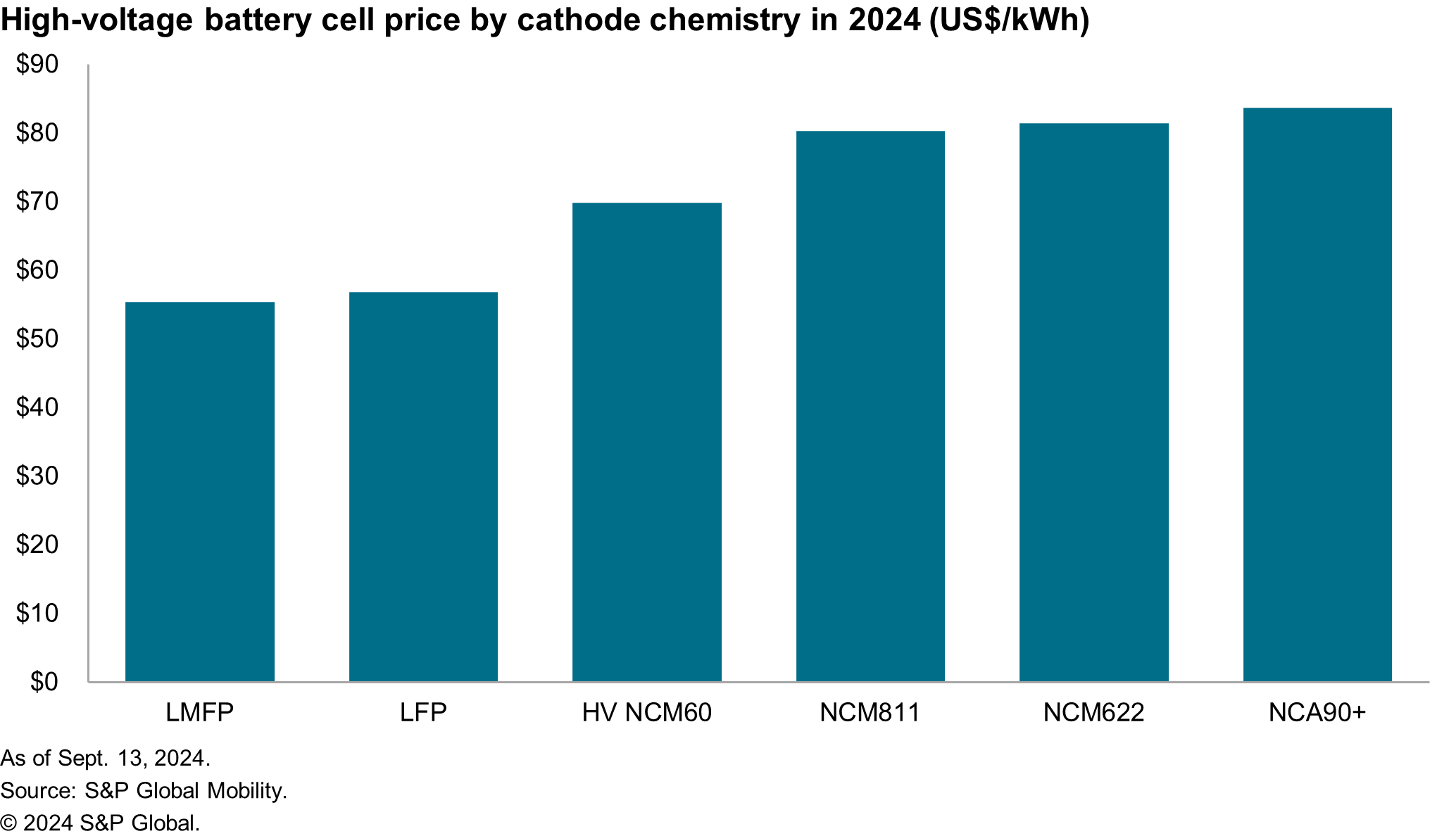

Lastly, as has been seen on this evaluation of battery chemistries,

value is a serious parameter within the decision-making tradeoffs OEMs and

suppliers need to make of their pursuit of the fitting battery

chemistry for his or her use case. Value can be one of many principal drivers

of EV adoption. It was usually held that EV gross sales would solely take off

as soon as EV batteries achieved value parity with the ICE. This stage was

deemed to be on the US$100 per kWh value level for the battery

pack. A number of chemistries are actually at that stage in accordance with the

value mannequin developed by S&P International Mobility.

Conclusion

The evolution of EV battery know-how displays a mix of

historic developments, rising improvements, and market calls for.

Finally, the continued evolution of battery know-how can be

pivotal in driving the adoption of electrical autos, making them

extra accessible and interesting to shoppers whereas contributing to a

extra sustainable automotive panorama. The continued pursuit of

cost-effective, high-performance batteries is not going to solely affect

the trajectory of the EV market but in addition play a vital position in

addressing world vitality and environmental challenges.

Get excessive voltage battery forecast information

Watch the Webinar: Accelerating Sustainable Mobility via

Battery Provide Chain Administration